Manufacturing Energy Efficiency AI

AI energy optimization delivers 12-30% cost reduction and significant CO₂ savings. Learn implementation strategies with 2.5-year ROI payback periods.

Manufacturing Energy Efficiency with AI: Reduce Costs & Carbon

What is Manufacturing Energy Efficiency AI?

Manufacturing energy efficiency AI refers to the use of artificial intelligence systems to monitor, analyze, and optimize energy consumption across manufacturing operations in real-time. It describes how machine learning models process operational data, sensor inputs, production schedules, and environmental factors to reduce energy waste and support sustainability and operational efficiency while maintaining production output and quality.

Quick Answer

AI for Manufacturing Energy Efficiency optimizes consumption patterns in real-time, reducing energy bills by 12-30% and lowering carbon emissions. By analyzing production schedules, weather data, and equipment performance, AI systems micro-adjust HVAC, lighting, and machinery to consume energy only when needed. This typically delivers a 200-400% ROI with a payback period of just 18-36 months.

For modern manufacturers, this isn’t just about saving money—it’s the fastest way to meet Scope 1 and Scope 2 sustainability targets.

Quick Facts

| Metric | AI Energy Impact |

|---|---|

| Cost Reduction | 12% – 30% reduction in utility bills |

| Payback Period | 1.5 – 3 years (Average ROI) |

| CO2 Reduction | 14,000 – 28,000 kg per facility |

| Standards | Supports ISO 50001 & ESG Compliance |

| Cooling Efficiency | Up to 40% reduction (DeepMind benchmark) |

Key Questions This Article Answers

How does AI actually optimize manufacturing energy?

AI optimizes manufacturing energy through reinforcement learning algorithms that analyze real-time data from IoT sensors, production schedules, weather forecasts, and equipment performance to dynamically adjust HVAC systems, lighting, and machinery loads. This micro-adjustment approach—such as pre-cooling buildings during off-peak hours and orchestrating equipment startup sequences—reduces energy consumption while maintaining production output. Read detailed explanation

What sensors are required for data collection?

Split-core CT clamps are recommended for 80% of manufacturing assets, offering ±1% accuracy without requiring downtime for installation. These non-invasive sensors clip onto existing wires to measure current draw, providing sufficient granularity for optimization at a fraction of the cost of inline digital meters. Wireless IoT sensors complement this for hard-to-reach equipment. See sensor selection guide

How does AI help with ISO 50001 certification?

AI accelerates ISO 50001 certification by automating energy reviews, generating Pareto charts of significant energy users instantly, and creating dynamic baselines using regression models that prove understanding of energy drivers to auditors. Real-time tracking of energy performance indicators and automated IPMVP-compliant savings verification reports demonstrate continual improvement, reducing certification time by 50%. Learn about ISO 50001 compliance

What is the typical implementation roadmap?

Implementation follows an 8-week roadmap: Week 1 (energy audit and hardware survey), Week 2 (connectivity and CT clamp installation), Week 3 (baseline learning phase), Week 4 (advisory mode deployment), Weeks 5-8 (closed-loop automation with guardrails), and Month 3 (verification and reporting). This rapid deployment enables savings to begin within 2 months. View complete roadmap

How do I present the financial case to a CFO?

Frame energy AI in financial terms: energy efficiency becomes “EBITDA improvement” (100% of savings to bottom line), predictive maintenance becomes “risk mitigation” (insuring against $500K unplanned outages), carbon reduction becomes “cost of capital” (green manufacturing lowers interest rates on green bonds), and asset health becomes “ROA improvement” (extending equipment life 5+ years). Energy AI offers positive NPV in year 1. See CFO pitch framework

1. The Energy Crisis in Manufacturing

Energy is no longer a fixed cost; it is a volatile variable that threatens margins. Since 2020, industrial energy costs have risen by over 50% in many regions.

- **Carbon Pricing

Learn more about AI implementation costs.**: Global regulatory fragmentation means carbon taxes are becoming a material line item.

- Grid Instability: Renewable integration is causing more frequent power quality issues and brownouts.

- Stakeholder Pressure: Customers are demanding low-carbon products (Scope 3 emissions).

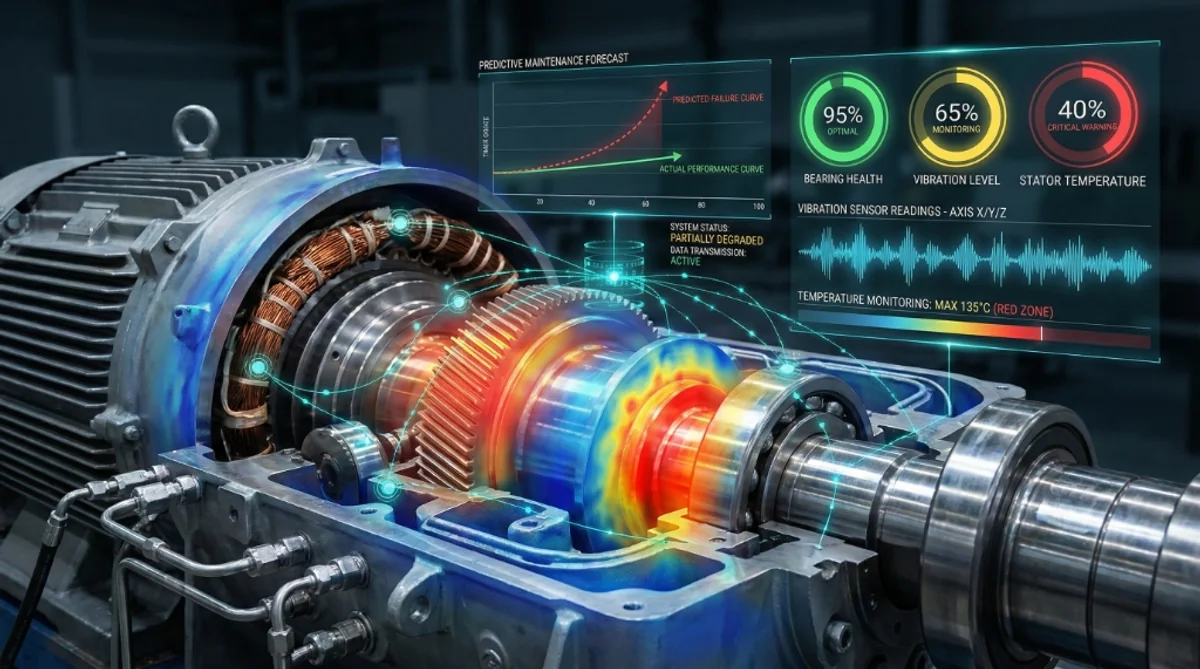

2. Technical Deep Dive: How AI Optimizes Energy

AI does not just “turn things off.” It models the complex thermodynamics of your facility.

A. Reinforcement Learning for HVAC (The “DeepMind” Approach)

Traditional HVAC uses PID controllers with static setpoints (e.g., “Keep room at 21°C”). AI uses Reinforcement Learning (RL). It learns the “physics” of the building.

- Input: Weather forecast, production schedule, current occupancy, machine heat output.

- Action: Pre-cool the building at 4 AM when energy is cheap, then coast through the afternoon peak.

- Result: 40% reduction in cooling energy (verified by Google DeepMind data centers).

B. Intelligent Load Balancing

Factories often hit “Peak Demand” charges because 5 large motors start simultaneously. AI orchestrates the startup sequence.

- Logic: “Compressor A is starting; wait 15 seconds before starting Chiller B.”

- Impact: Reduces peak power draw by 15-20% without affecting production throughput.

C. The “Digital Energy Twin”

We build a virtual replica of your factory’s energy flows.

- Simulation: “What happens to our KWh per unit if we move Schedule B to the night shift?”

- Identification: Instantly finding “Energy Vampires”—machines that are idling but drawing full power.

- Scenario Planning:

- Scenario 1: Replace gas furnace with electric. (CAPEX: $2M, Energy Savings: $500k/yr).

- Scenario 2: Install VFDs on all pumps. (CAPEX: $200k, Energy Savings: $150k/yr).

- Conclusion: Scenario 2 offers better immediate ROI.

3. Sensor Selection Guide: Getting the Data

You cannot save what you cannot measure. Here is how to meter your facility without rewiring everything.

| Sensor Type | Best For | Installation Difficulty | Cost | Data Granularity |

|---|---|---|---|---|

| Utility Meter (Main) | Total Plant Bill | N/A (Existing) | $0 | Low (Monthly) |

| Inline Digital Meter | New Machines / Panels | High (Requires Shutdown) | $$$ | High (Voltage, PF, Harmonics) |

| Split-Core CT Clamp | Existing Wires | Low (Clip-on active wire) | $$ | Medium (Amps -> kW estimate) |

| Rogowski Coil | Large Busbars (>1000A) | Low (Flexible rope) | $$$ | High |

| Wireless IoT Sensor | Hard-to-reach Motors | Very Low (Battery powered) | $ | Medium (Vibration + Temp) |

Recommendation: Use Split-Core CTs for 80% of your assets. They are accurate enough (±1%) for optimization and require zero downtime to install.

4. Achieving ISO 50001 Certification with AI

ISO 50001 is the global gold standard for Energy Management Systems (EnMS). Implementing AI makes certification 50% faster.

Step 1: Energy Review (Automated)

Requirement: “Analyze energy use and consumption.” Manual Way: Consultants spend weeks reading meters. AI Way: The dashboard automatically generates the Pareto Chart of significant energy users (SEUs) instantly.

Step 2: Energy Baseline (EnBs) (regression Analysis)

Requirement: “Establish a baseline(s) using data.” Manual Way: Using last year’s average. AI Way: Creating a Dynamic Baseline. The AI builds a regression model: $Expected Energy = (Production \times 1.2) + (Degree Days \times 0.5) + Base Load$ This proves to the auditor that you understand the drivers of your energy use.

Step 3: Performance Indicators (EnPIs)

Requirement: “Monitor EnPIs.” AI Way: Real-time tracking of “kWh per Widget” or “kWh per Operating Hour.”

Step 4: Continual Improvement

Requirement: “Demonstrate energy performance improvement.” AI Way: The “Savings Verification Report” (IPMVP compliant) automatically calculates savings vs. the dynamic baseline, differentiating between “We saved energy because production was low” and “We saved energy because we were efficient.”

3. Proven Case Studies in Energy AI

Google DeepMind: 40% Cooling Efficiency

- Challenge: Massive data centers consuming city-sized amounts of power.

- Solution: AI trained on historical sensor data (temps, flows, fan speeds).

- Outcome: Consistently reduced cooling energy bill by 40%, a breakthrough in industrial thermodynamics.

Lenovo Manufacturing: 30% Savings

Using the “Leap” IoT platform:

- Challenge: Managing energy across a global manufacturing footprint.

- Action: Connected smart meters to air compressors and SMT lines.

- Result: 30% overall energy cost reduction and 12% specific reduction in air compressor usage.

- Payback: Achieved ROI in 2.5 years.

ThroughPut AI: The $3M Sustainability Win

- Context: A large industrial facility facing ESG pressure.

- Intervention: Analyzed operational bottlenecks that caused energy waste (idling machines).

- Impact:

- $3 Million immediate financial savings.

- 14,000 - 28,000 kg CO2 reduction per facility.

- 18-26% operational capacity freed up.

- Equivalent to removing 6,000+ cars from the road.

4. Sustainability ROI: The “Double Bottom Line”

Investments in Energy AI deliver two returns simultaneously:

| Metric | Financial Value | Sustainability Value |

|---|---|---|

| Energy Reduction (kWh) | Lower utility bills (Scope 2) | Reduced Carbon Footprint |

| Peak Shaving | Lower demand charges | Reduced grid stress |

| Predictive Maintenance | Lower spare parts cost | Reduced waste/scrap (Scope 3) |

| Asset Life Extension | Deferred CAPEX | Circular Economy contribution |

Typical Results:

- Cost Reduction: 12-30%

- Consumption Drop: 10-20%

- Global Potential: 15% of all global energy usage could be saved by 2040 via industrial AI.

6. Implementation Roadmap: 8 Weeks to Savings

Week 1: The Energy Audit & Hardware Survey

- Goal: Find the leaks.

- Action: Walk the floor. Identify the “Big 5” consumers.

- Checklist:

- List all motors > 50HP.

- Check if SCADA is accessible via Modbus-TCP.

- Photograph electrical panels for CT Clamp fitment.

- Metric: Baseline kW/unit produced.

Week 2: Connectivity & Installation

- Goal: Get the data flowing.

- Action: Deploy Edge Gateway. Install CT Clamps.

- Tech Stack: MQTT over Cellular (to avoid IT firewall delays).

- Check: Ensure data granularity is < 15 minutes (ideally 1 minute).

Week 3: Baseline & Learning Phase

- Goal: Learn “Normal.”

- Action: AI observes operations. It learns that “Process A always spikes energy usage at 10 AM.”

- Calibration: Verify the sensor readings match the utility bill (aim for < 2% variance).

Week 4: Deployment (Advisory Mode)

- Goal: Recommendations.

- Action: Dashboard starts suggesting: “Turn off Compressor 3; pressure is sufficient.”

- Review: Plant Manager validates suggestions. “Is this safe? Yes.”

Week 5-8: Deployment (Closed Loop Automation)

- Goal: Automation.

- Action: Enable AI to directly control setpoints via the PLC.

- Safety: set “Guardrails” (e.g., “Never turn off Chiller if Temp > 25°C”).

- Result: “Set-it-and-forget-it” optimization.

Month 3: Verification & Reporting

- Action: Generate the first savings report.

- Apply: Submit data for Utility Rebates (many utilities pay for confirmed efficiency projects).

- Certify: Begin ISO 50001 documentation using the AI logs.

7. Advanced Strategies: Scope 3 & Microgrids

Once you have optimized your own walls (Scope 1 & 2), the next frontier is the grid and the supply chain.

A. Renewables Integration & Microgrid Management

Many manufacturers are installing rooftop solar or wind turbines to reduce grid dependency. The Challenge: Solar generation peaks at noon; manufacturing demand might peak at 4 PM. The AI Solution: Intelligent Battery Storage (BESS) management.

- Store: The AI charges batteries when solar is high and grid prices are low.

- Discharge: It discharges during peak demand hours or when grid prices spike.

- Island Mode: In unstable regions, the AI can seamlessly switch the facility to “Island Mode” during a grid blackout, keeping critical lines running on battery/generator power.

B. Tackling Scope 3 Emissions (The Supply Chain)

Scope 3 (supply chain) accounts for 80% of a typical manufacturer’s carbon footprint. AI is the key to measuring this.

- Supplier Data ingestion: The platform ingests energy data from your Tier 1 suppliers.

- Carbon Accounting: It calculates the “Embedded Carbon” of every raw material shipment.

- Optimization: “Supplier A uses green hydro-power. Supplier B uses coal. Switching reduces our product’s carbon footprint by 15%.“

8. Common Pitfalls in Energy AI Projects

Why do some projects fail? Avoid these traps.

Trap 1: “The Data Lake Swamp”

Mistake: Dumping all data into a lake without a clear use case. Fix: Start with a hypothesis. “We believe Chiller 4 is inefficient.” only collect data relevant to proving/disproving that.

Trap 2: Alert Fatigue

Mistake: Designing a system that emails the maintenance manager every time a variable shifts 1%. Result: They turn off notifications. Fix: Use “intelligent filtering.” Only send an alert if the anomaly persists for >30 minutes and costs >$50.

Trap 3: Ignoring the Human Element

Mistake: Installing a “Black Box” that changes setpoints without explaining why. Operators will override it. Fix: Explainability. The dashboard must say: “Turned off loading pump because buffer tank is full.” Build trust before automation.

Trap 4: Wi-Fi Reliability

Mistake: Relying on factory Wi-Fi for sensor data. Industrial environments are full of metal interference. Fix: Use robust industrial protocols like LoRaWAN, Zigbee, or cellular (NB-IoT) for sensor networks.

9. The Financial Case for the CFO

When pitching this project, speak the language of finance, not engineering.

| Engineering Term | CFO Term | The Pitch |

|---|---|---|

| Energy Efficiency | EBITDA Improvement | ”This project drops 100% of savings to the bottom line.” |

| Predictive Maintenance | Risk Mitigation | ”We are insuring against a $500k unplanned outage.” |

| Carbon Reduction | Cost of Capital | ”Green manufacturing lowers our interest rates on green bonds.” |

| Asset Health | ROA (Return on Assets) | “We get 5 more years of life out of our expensive chillers.” |

The Bottom Line: Energy AI is one of the few projects with a Positive NPV (Net Present Value) in year 1.

See how impactful small efficiency gains can be on your factory’s bottom line.

Estimate Your Potential Savings

Based on industry benchmarks and typical deployment scenarios. Actual results may vary based on facility size, equipment age, and data readiness.

Frequently Asked Questions

How accurate is the ROI calculation?

Very accurate. We baseline your usage for 30 days. Any reduction after that is directly attributable to the system. We follow the IPMVP (International Performance Measurement and Verification Protocol).

Does this help with ISO 50001?

Yes. ISO 50001 requires “continuous improvement” in energy performance. AI provides the automated data collection, baselining, and reporting required for certification.

Can we do this without new sensors?

Sometimes. We can pull data from existing BMS (BACnet), SCADA (Modbus), or Utility Smart Meters. If needed, we use non-invasive Clamp-On CTs (Current Transformers).

What about “Peak Shaving”?

AI excels at this. Peak Demand charges can be 40% of your bill. AI predicts when you are about to hit a new peak and automatically dims non-critical lighting or cycles HVAC fans.

Is it secure?

Yes. We offer air-gapped options for critical infrastructure. Data flows out of the PLC via diode protection, preventing any external control unless explicitly authorized.

How does it affect equipment life?

It extends it. Short-cycling kills motors. AI smooths out control loops (e.g., using VFDs instead of On/Off), reducing mechanical stress.

Can it handle renewable inputs?

Yes. If you have onsite solar, the AI aligns energy-intensive tasks with peak generation times to maximize self-consumption.

Summary

Energy management is no longer a purely operational concern—it is a strategic necessity for the modern industrial enterprise. By implementing AI-driven monitoring and automation, manufacturers can flip the script on rising utility costs, turning energy efficiency into a high-ROI engine for both financial growth and environmental leadership.

Recommended Follow-Up

- Smart Factory Roadmap: Read about the evolution of Industry 4.0 & Smart Manufacturing.

- Deployment Guide: Learn how to start your journey with our Manufacturing AI Implementation Guide.

- Network Optimization: Explore how AI improves Manufacturing Supply Chain Optimization.

- Custom Assessment: Request an Industrial Energy Audit to find your facility’s specific savings potential.

Next Steps: Stop Paying for Wasted Energy

Ready to cut your manufacturing energy bills by 30%? Here’s how:

- Request an energy assessment with AgenixHub to baseline your usage.

- Identify your “Big 5” consumers—the motors and chillers draining your margins.

- Analyze your potential ROI using our Manufacturing ROI Calculator.

- Deploy a 30-day monitoring pilot to see real-time “Energy Vampire” identification.

Get Started: Schedule a free consultation to discuss an energy assessment for your facility.

Analyze ROI: Use our Manufacturing ROI Calculator to see the potential savings for your factory.

Don’t let rising energy costs erode your competitiveness. Contact AgenixHub today to optimize your facility’s footprint.