Industry 4.0 Smart Manufacturing 2025

Industry4.0 market reaches $862B by 2034. Comprehensive guide to smart manufacturing adoption, ROI metrics (30-50% efficiency gains), and technology stack.

Industry 4.0 and Smart Manufacturing: The Complete 2025 Guide

What is Industry 4.0?

Industry 4.0 refers to the fourth industrial revolution characterized by the integration of cyber-physical systems, Internet of Things, cloud computing, and artificial intelligence into manufacturing and industrial processes. It describes how smart factories leverage interconnected machines, real-time data analytics, and autonomous decision-making to create adaptive production systems that optimize efficiency, quality, and customization while fundamentally transforming traditional manufacturing paradigms.

Quick Answer

Industry 4.0 (the Fourth Industrial Revolution) is the integration of intelligent digital technologies into manufacturing and industrial processes. By combining AI, the Internet of Things (IoT), Cloud Computing, and Digital Twins, it creates “Smart Factories” where machines communicate, analyze data, and optimize large-scale production autonomously.

The market is projected to reach $862 billion by 2034, driven by the need for agility. Manufacturers adopting Industry 4.0 typically realize 30-50% efficiency gains and a 45-70% reduction in downtime.

Market Breakdown

The acceleration isn’t uniform. High-value manufacturing leads the charge:

- Automotive: Leading adopter (Robotics & Ai-driven QA).

- Pharmaceuticals: Driven by “Pharma 4.0” regulatory compliance and batch tracing.

- Electronics: Focusing on yield optimization at the nano-scale.

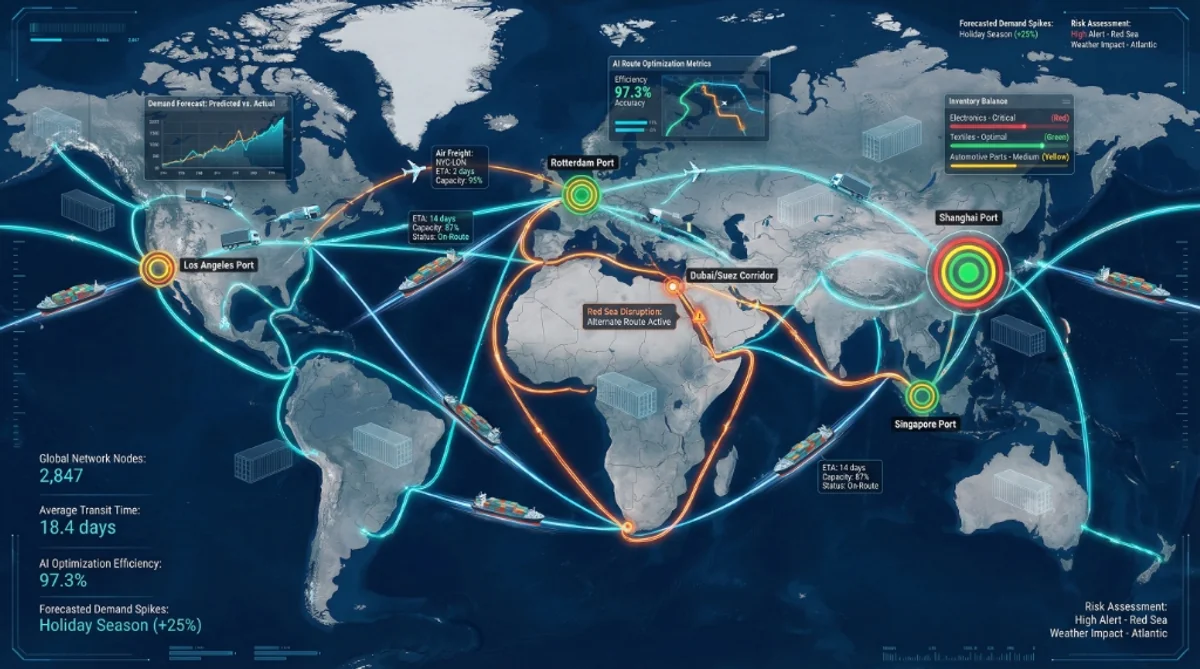

- FMCG: Prioritizing supply chain agility and mass customization.

Quick Facts

| Metric | Industry 4.0 Impact |

|---|---|

| Market Value | $862 Billion projected by 2034 |

| Efficiency Gains | 30% – 50% increase in output |

| Downtime Reduction | 45% – 70% decrease in unplanned stops |

| Cycle Time | 30% improvement with digital twins |

| ROI Timeline | Payback typically within 6-12 months |

Key Questions

- What are the core Industry 4.0 technologies?

- Is Industry 4.0 only for big companies?

- What is the difference between 3.0 and 4.0?

- What are the different types of Digital Twins?

- What is the five-stage roadmap to AI?

The Evolution: From Steam to Sensors

To understand where we are going, we must understand how we got here.

Industry 1.0 (1784): Mechanization

- Power Source: Water and Steam.

- Innovation: The mechanical loom.

- Shift: Moving from “Cottage Industry” (making things at home) to “Factory Production” (centralized work).

- Limitation: Machines were purely mechanical; no feedback loops.

Industry 2.0 (1870): Mass Production

- Power Source: Electricity.

- Innovation: The Assembly Line (Henry Ford).

- Shift: Division of labor. Workers performed one repetitive task optimized for speed.

- Limitation: Extremely rigid. “You can have any color as long as it’s black.” Changing a product line took months.

Industry 3.0 (1969): Automation

- Power Source: Electronics and IT.

- Innovation: The PLC (Programmable Logic Controller) and Robotics.

- Shift: Robots took over dangerous/heavy tasks. Computers began storing data.

- Limitation: “Islands of Automation.” The robot knew what it was doing, but the inventory system didn’t. Systems were siloed.

Industry 4.0 (Today): Cyber-Physical Systems

- Power Source: Data.

- Innovation: IoT and AI.

- Shift: Machines talk to machines (M2M). The product talks to the machine (“I am a sedan, paint me blue”).

- Breakthrough: Mass Customization at Mass Production costs.

What about Industry 5.0?

While we are still implementing 4.0, the concept of Industry 5.0 is emerging.

- Focus: Human-Centricity, Sustainability, and Resilience.

- Shift: Bringing the human back into the loop to work alongside “Cobots” (Collaborative Robots) for hyper-personalization.

Global Adoption Landscape: Who is Winning?

The race to smart manufacturing is a geopolitical battleground.

1. Germany (The Inventor)

Germany coined the term “Industrie 4.0” in 2011.

- Strategy: “High-Tech Strategy 2025”. Focus on standardization (RAMI 4.0) and interoperability.

- Strength: World-class machinery (Siemens, Bosch, Kuka).

- Status: High maturity in automotive and engineering.

2. China (The Scaler)

- Strategy: “Made in China 2025”.

- Goal: Move from “World’s Factory” (cheap labor) to “World’s High-Tech Lab”.

- Strength: Massive scale adoption of 5G in factories.

- Status: Rapidly leapfrogging Industry 3.0 directly to 4.0.

3. United States (The Software Giant)

- Strategy: “Smart Manufacturing Leadership Coalition”.

- Strength: Software, Cloud (AWS/Azure), and AI innovation.

- Status: Leading in the “IT” side (analytics), but sometimes lagging in the “OT” side (retrofitting old factories).

Common Questions

What are the 4 main technologies of Industry 4.0?

- Internet of Things (IoT): Sensors and networks connecting physical machines to the digital world.

- Artificial Intelligence (AI): The “brain” that analyzes data to predict failures and optimize flows.

- Cloud & Edge Computing: The infrastructure that stores and processes the massive data streams.

- Digital Twins: Virtual replicas of physical assets used for simulation and testing.

Is Industry 4.0 just for big companies?

No. In fact, small-to-mid-sized manufacturers (SMMs) often see the fastest ROI. Because they have less bureaucracy and legacy infrastructure, SMMs can deploy targeted “point solutions” (like adding sensors to a single critical CNC machine) in weeks, rapidly gaining competitive advantage over slower-moving giants.

What is the difference between Industry 3.0 and 4.0?

- Industry 3.0 (1970s): Automation via computers and electronics (Robots doing what they are told).

- Industry 4.0 (Today): Cyber-Physical Systems (Machines talking to each other and making autonomous decisions based on data).

Example:

- Industry 3.0: A robot paints a car door.

- Industry 4.0: The robot detects the humidity is high, adjusts the paint spray pressure automatically, and alerts maintenance that the nozzle is clogging.

Deep Dive: The Core Technologies

1. Artificial Intelligence (AI) & Machine Learning

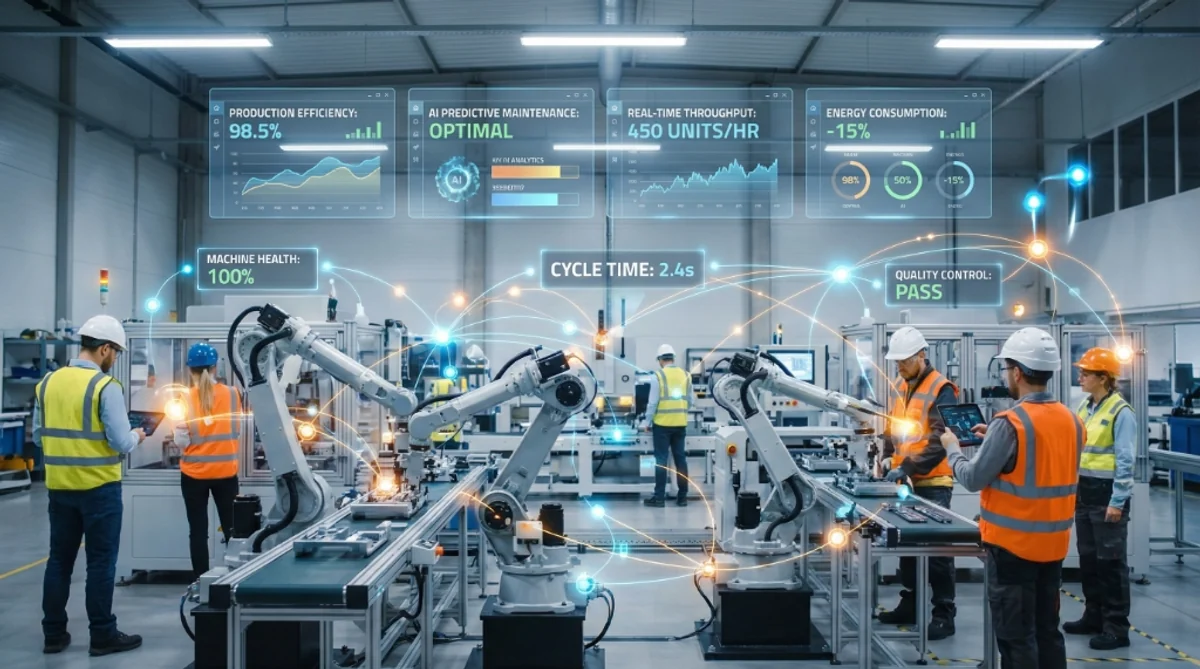

AI is the engine of Industry 4.0. It processes the terabytes of data generated by sensors to find patterns humans miss.

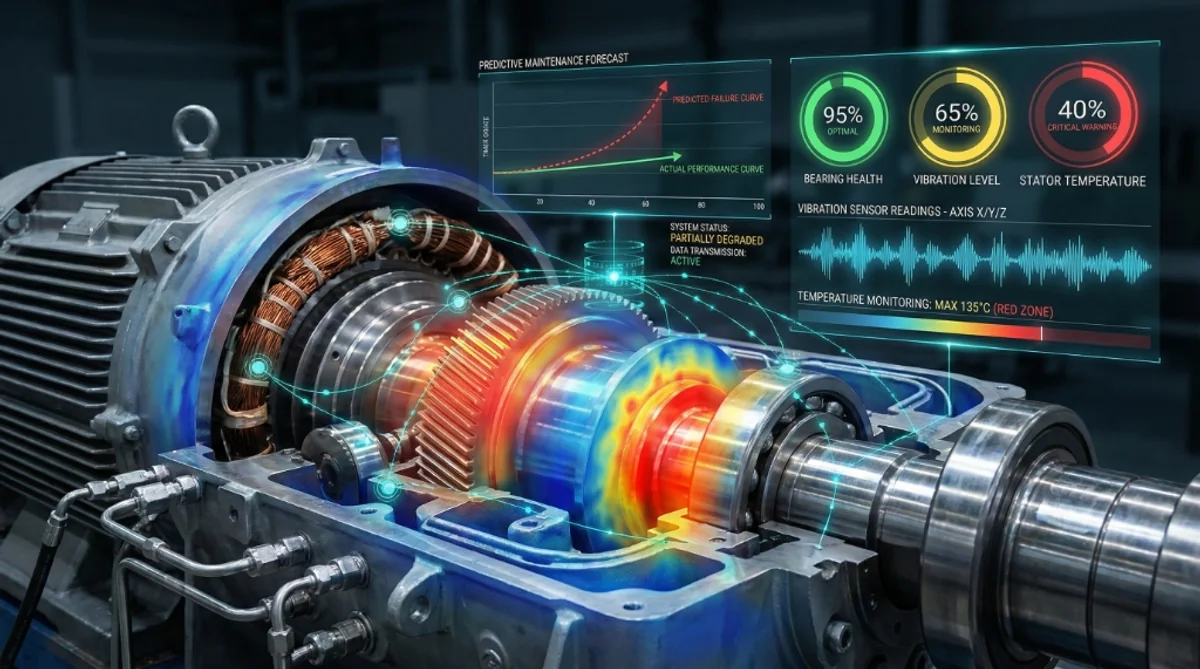

- Use Case: Predictive Maintenance (Predicting failures before they happen).

- Value: $500B+ annual value creation across the sector.

2. Digital Twins

A Digital Twin is a live virtual model of a physical asset.

- Simulation: Test a new production schedule in the digital twin to see if it causes bottlenecks before risking real production.

- Market: Growing from $21B to $149B by 2030.

3. Industrial IoT (IIoT) Connectivity

Connectivity is the nervous system. But it’s not just “plugging it in.” It involves a complex protocol stack.

The Protocol Wars: OT vs IT

- OPC-UA (Open Platform Communications Unified Architecture): The universal translator. It allows a Siemens PLC to talk to a Honeywell sensor securely.

- MQTT (Message Queuing Telemetry Transport): Lightweight messaging for the cloud. It’s how thousands of sensors stream data without clogging the bandwidth.

- Sparkplug B: The “Industrial” wrapper for MQTT that ensures data isn’t just a number, but has context (e.g., “This ‘45’ is Celsius, not Fahrenheit”).

Edge vs. Cloud Architecture

- Edge Computing: Processing data on the machine (e.g., stopping a robot arm in 10ms).

- Cloud Computing: Processing aggregated data (e.g., training a predictive model on a month of history). The Trend: Moving AI inference to the Edge to avoid latency, while keeping “Learning” in the Cloud.

4. Advanced Digital Twins

It’s not just a 3D model. We classify Twins into three maturity levels:

Type A: Product Twin (Design)

- What: A CAD model of the product as designed.

- Use: Simulating stress tests before cutting metal. “Will this landing gear break?”

Type B: Production Twin (Process)

- What: A simulation of the factory floor.

- Use: “If we speed up Conveyor 4, will the Robot Arm keep up?” (Bottleneck analysis).

Type C: Performance Twin (Operations)

- What: A live data connection to the real asset.

- Use: Receiving real-time torque data to predict bearing failure. Value: Companies using detailed Performance Twins see a 30% improvement in cycle times.

Assess Your Maturity

Are you still in Industry 3.0? Take this 5-question assessment to find your digital maturity level.

Industry 4.0 Maturity Assessment

Answer 5 questions to benchmark your Smart Manufacturing readiness.

1. How is data collected from your machines?

2. How do you handle equipment maintenance?

3. How digital is your supply chain?

4. How are quality checks performed?

5. How do you make production decisions?

Implementation Strategy: The “Smart” Roadmap

Stage 1: Connectivity (Get Connected)

- Goal: Kill the clipboard.

- Action: Connect machines to a central gateway. Even old analog machines can be retrofitted with cheap IoT sensors.

Stage 2: Visibility (See What’s Happening)

- Goal: Real-time dashboard.

- Action: Visualize OEE (Overall Equipment Effectiveness) in real-time. Know exactly which machine is down and why.

Stage 3: Transparency (Understand Why)

- Goal: Root cause analysis.

- Action: Compare data streams. “Why does Scrap Rate spike every Tuesday at 2 PM?” (AI finds the correlation).

Stage 4: Predictability (Know What Will Happen)

- Goal: No surprises.

- Action: Deploy Predictive Maintenance and Demand Forecasting models.

Stage 5: Adaptability (Autonomous Action)

- Goal: Self-healing systems.

- Action: Machines automatically slow down to prevent overheating while ordering their own spare parts.

The Landscape: Platform Providers

You don’t have to build this from scratch. The ecosystem is mature.

- The Giants: Siemens (MindSphere), Rockwell (FactoryTalk), GE Digital (Predix). Great for massive, homogenous environments.

- The Hyperscalers: AWS Industrial, Microsoft Azure IoT. Powerful toolkits for developers.

- The Agile Specialists: AgenixHub. Focused on rapid deployment, private AI, and specific outcomes (ROI in 90 days) without the multi-year consulting contracts.

Frequently Asked Questions

What is the biggest barrier to adoption?

Culture, not technology. The “we’ve always done it this way” mindset is the #1 killer of Industry 4.0 projects. Successful leaders focus on Change Management—showing operators how AI makes their specific job easier, not harder.

Is cloud infrastructure required?

No. Many manufacturers prefer On-Premises or Edge Computing for security and latency reasons. Modern Industry 4.0 stacks can run entirely within your factory firewall (Air-Gapped).

What is the ROI timeline

Learn more about how long AI implementation typically takes.? Incremental wins pay for the journey.

- months 1-3: Real-time visibility (5-10% productivity bump).

- months 3-6: Predictive pilots (Avoid 1-2 shutdowns, paying for the pilot).

- months 12+: Full smart factory integration (30-50% efficiency gain).

How does 5G fit in?

5G allows for “Mobile Robotics” and massive sensor density (1 million devices per sq km) without cabling. It enables AGVs (Automated Guided Vehicles) to move freely and stream HD video for navigation.

Key Takeaways

- Data is the New Oil: But only if you refine it. Collecting data without AI is just hoarding.

- Start Small: Don’t try to digitally transform the whole factory at once. Transform one line, prove the value, then scale.

- Security First: As you connect machines, you increase your attack surface. OT (Operational Technology) security must be part of the design.

5. Security: The “Zero Trust” Factory

The biggest risk in Industry 4.0 is not technology; it’s Ransomware. Connecting OT (Operational Technology) to IT (Information Technology) opens the door to hackers.

The Old Way: Air Gap (The Myth)

“My factory isn’t connected to the internet, so I’m safe.” Reality: A contractor plugs in a USB drive to update a PLC, and the malware spreads. Stuxnet proved the Air Gap is a myth.

The New Way: The Purdue Model 2.0 & Zero Trust

We segment the network into layers (The Purdue Model):

- Level 0 (Physical): Sensors/Motors.

- Level 1 (Control): PLCs/HMIs.

- Level 2 (Supervisory): SCADA.

- Level 3 (Operations): MES/Historian.

- Level 4 (Business): ERP/Email.

Zero Trust Rule: Level 4 (Email) can never talk directly to Level 1 (PLC). We use Industrial DMZs (Demilitarized Zones) and Data Diodes (hardware that physically allows data to flow only one way: Out).

6. Workforce 4.0: Humans in the Loop

Industry 4.0 is not about replacing people; it’s about “Augmenting” them. The “Operator” becomes the “Process Manager.”

The Skills Shift

- Yesterday: Manual lifting, visual inspection, turning knobs.

- Tomorrow: Analyzing subtle data trends, programming cobots, maintaining sensors.

Augmented Reality (AR) on the Floor

- Case: A technician needs to fix a pump.

- Tech: They wear AR glasses (like HoloLens).

- Effect: The glasses overlay the “Digital Twin” on the physical pump, showing a hologram of the internal broken bearing and a step-by-step repair guide.

- Result: 50% faster repair times and near-zero training requirement for new hires.

7. Platform Comparison: Choosing Your Stack

| Feature | Siemens / Rockwell (The Incumbents) | AWS / Azure (The Cloud Giants) | AgenixHub (The Agile Integrator) |

|---|---|---|---|

| Best For | Massive, standardized factories using one hardware brand. | Developers building custom apps from scratch. | Mid-to-Large Manufacturers wanting ROI in < 90 days. |

| Strengths | Deep hardware integration, rock-solid reliability. | Infinite scalability, advanced AI toolkits. | Speed, Vendor-Agnostic (We connect Siemens to Allen-Bradley), Custom AI Models. |

| Weaknesses | Rigid, expensive, slow to update. | Requires an army of software engineers to build. | - |

| Cost | $$$$ (CapEx heavy) | $$ (OpEx, but engineer salaries are high) | $$$ (Balanced Value) |

| Deployment | 12-24 Months | 6-18 Months | 3-6 Months |

8. Implementation Checklist for 2025

Don’t boil the ocean. Follow this sprint-based approach.

Sprint 1: The “Low Hanging Fruit” (Weeks 1-4)

- Audit: Inventory all assets (Make/Model/Protocol).

- Gateway: Install an Edge Gateway to suck data from the easiest machine.

- Dashboard: Display one metric (e.g., Temperature) on a TV screen.

- Goal: Prove connectivity works.

Sprint 2: The “OEE Pilot” (Weeks 5-8)

- Connect: Wire up one production line (Bottle Neck asset).

- Metric: Calculate live OEE (Availability x Performance x Quality).

- Win: Identify why the line stops (e.g., “Micro-stops due to sensor misalignment”).

- Goal: 5-10% productivity bump.

Sprint 3: The “AI Layer” (Months 3-6)

- Analyze: Feed history to an Anomaly Detection model.

- Predict: Start predicting failures (Predictive Maintenance).

- Goal: Eliminate unplanned downtime on the Pilot line.

Sprint 4: Scale (Months 6+)

- Replicate: Copy the “Stack” to Line 2, Line 3, Factory B.

- Integration: Feed the new data into SAP/ERP for automated ordering.

Summary

Industry 4.0 represents a fundamental shift in how products are designed, manufactured, and serviced. By delivering 30-50% efficiency gains and massive reductions in downtime, smart manufacturing technology provides the foundation for sustainable competitive advantage in the 2025 economy.

Recommended Follow-Up

- Sector Deep Dive: Read our Manufacturing AI Implementation Guide for specific deployment steps.

- Case Studies: Explore Automotive AI ROI Case Studies for proven industrial results.

- Technology Foundation: See our guide on Predictive Maintenance to start your ROI journey.

- Agile Strategy: Learn how to optimize your Manufacturing Supply Chain.

Next Steps: Prepare for the AI Future

Ready to future-proof your organization? Here’s how:

- Take the Assessment above to know where you stand.

- Pick a Pilot: Identify one “dumb” process that costs you money.

- Calculate ROI using our AI ROI Calculator.

- Request a consultation with AgenixHub to discuss building your modular Industry 4.0 platform.

Get Started: Schedule a free consultation to discover how smart manufacturing can transform your organization.

Analyze ROI: Use our AI ROI Calculator to estimate the business impact of Industry 4.0 implementation.

The Fourth Industrial Revolution is happening with or without you. Don’t just observe the change—drive it. Contact AgenixHub today.