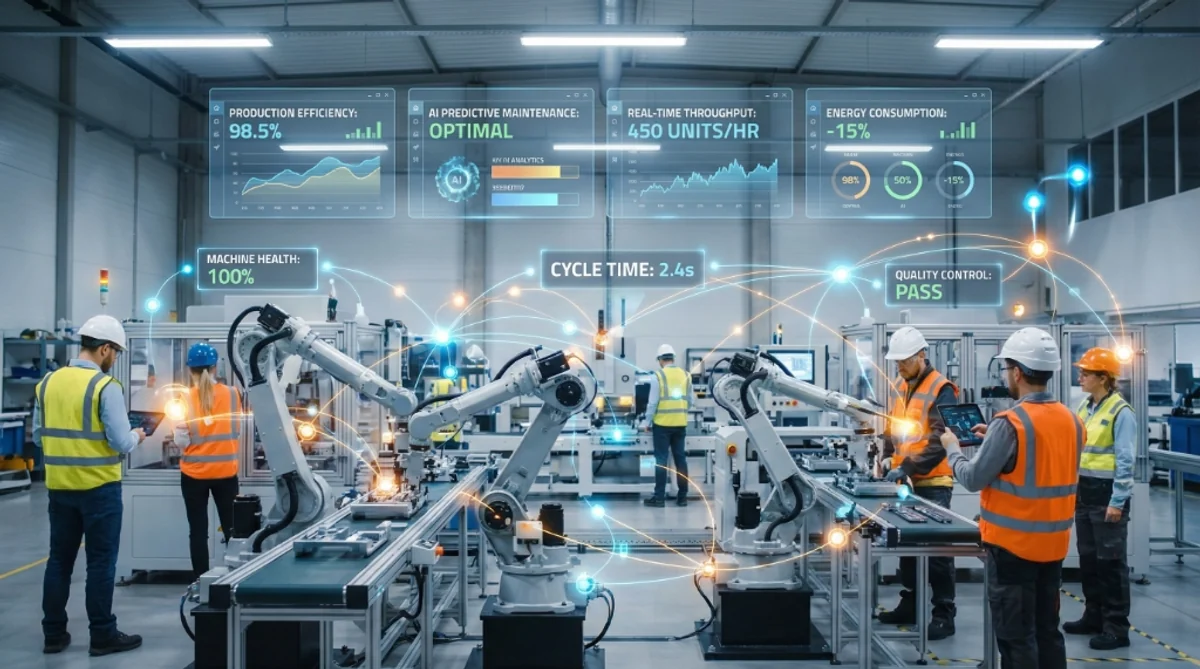

Manufacturing Predictive Maintenance 2025

Proven strategies to reduce downtime by 45% using AI. Learn how predictive maintenance works, required sensors, and ROI calculation.

Manufacturing Predictive Maintenance: A Comprehensive Guide (2025)

What is Predictive Maintenance?

Predictive maintenance refers to a data-driven maintenance strategy that uses artificial intelligence and machine learning to forecast equipment failures before they occur. It describes how organizations analyze real-time sensor data from machinery to detect anomalies, calculate remaining useful life, and schedule maintenance activities based on actual equipment condition rather than predetermined time intervals or reactive responses to breakdowns.

Quick Answer

Predictive Maintenance (PdM) uses AI to analyze data from sensors (vibration, temperature, acoustics) to predict equipment failure days or weeks before it happens. Unlike preventive maintenance which follows a schedule, PdM is condition-based, offering a 10:1 to 30:1 ROI by eliminating 70-75% of unexpected breakdowns and reducing maintenance costs by 25-40%.

For a typical mid-sized manufacturer, implementing PdM on critical assets is a core part of an AI Implementation Roadmap that can recover $500,000 to $2M annually in lost productivity.

Quick Facts

- Downtime Reduction: Up to 45%

- Maintenance Cost Savings: 25-40%

- ROI Ratio: 10:1 to 30:1

- Prediction Accuracy: 85-95%

- Asset Life Extension: Up to 30%

Key Questions

How does AI predict machine failure?

AI models establish a baseline of “normal” operation from sensor data and use machine learning algorithms like Random Forest or LSTM to detect subtle deviations that indicate developing faults like bearing wear or motor overheating.

What is the primary financial benefit of predictive maintenance?

The primary benefit is the elimination of unplanned downtime, which can cost automotive manufacturers as much as $22,000 per minute.

Do I need thousands of failure examples to train the AI?

No, modern anomaly detection techniques can establish a “normal” baseline and flag deviations without needing extensive historical failure data.

Common Questions

Why is predictive maintenance the #1 AI use case?

Unplanned downtime costs the manufacturing industry an estimated $50 billion annually.

For automotive manufacturers, a single minute of downtime can cost $22,000 ($1.3M per hour). Predictive maintenance directly attacks this cost center.

- Reliability: It transforms maintenance from “repair after break” to “repair before break.”

- Asset Life: By preventing catastrophic failures, it extends the useful life of machinery by up to 30%.

- Safety: Fewer emergency repairs mean fewer accidents during high-pressure fix situations.

What is the difference between Reactive, Preventive, and Predictive Maintenance?

| Strategy | Trigger | Cost Effect | Efficiency |

|---|---|---|---|

| Reactive | Run-to-failure | Highest (Emergency repairs + overtime + lost production) | Low |

| Preventive | Time-based (e.g., every 30 days) | Medium (Replaces good parts unnecessarily) | Medium |

| Predictive | Condition-based (AI alerts) | Lowest (Fix only when needed) | High |

How does AI predict equipment failure?

AI models learn the “fingerprint” of normal operation and detect subtle deviations that humans miss.

- Baseline: The AI learns what a healthy motor sounds and vibrates like at various speeds.

- Anomaly Detection: It spots a 2Hz vibration increase or a 5°C temperature rise—early signs of bearing wear.

- Prognostics: It calculates “Remaining Useful Life” (RUL)—e.g., “Main Conveyor Motor B will fail in 14 days.”

Technical Deep Dive: How It Works

1. Data Collection & Sensors

The foundation of PdM is data. You don’t always need new sensors; many modern PLCs already capture relevant data points.

- Vibration Sensors: Key for rotating machinery (motors, pumps, fans) to detect imbalance or bearing wear.

- Thermography/Temperature: Identifies overheating electrical components or friction points.

- Acoustic/Ultrasonic: Detects gas leaks or early-stage friction before vibration sensors can pick it up.

- Power Consumption: Current spikes often indicate a machine working harder than it should (e.g., dull tool or jammed intake).

2. Edge Computing vs. Cloud Analysis

- Edge AI: Runs directly on the machine or gateway. It processes high-frequency vibration data (thousands of samples per second) locally, sending only alerts to the cloud. This reduces latency and bandwidth costs.

- Cloud AI: Aggregates data from all machines to find long-term trends and train more complex models.

3. The AI Model: Algorithm Selection Guide

Choosing the right algorithm is the difference between accurate predictions and noise.

A. Random Forest (The workhorse)

Best for: Structuring data with clear features (e.g., temperature, pressure, vibration RMS). Pros: Highly interpretable, handles non-linear data well, requires less training data. Cons: struggles with raw waveform data. Use Case: Predicting pump failure based on SCADA logs.

B. Long Short-Term Memory (LSTM) Networks

Best for: Time-series data where the sequence matters. Pros: Remembers long-term dependencies (e.g., a gradual temperature rise over 3 months). Cons: Computationally expensive, hard to train. Use Case: Forecasting “Remaining Useful Life” (RUL) of a turbine engine.

C. Autoencoders (Unsupervised Learning)

Best for: Anomaly detection when you have no failure data. Pros: learns “normal” behavior and flags anything else. Cons: Can flag benign anomalies (like a new operational mode) as failures. Use Case: Monitoring a brand new production line with zero historical failure logs.

D. Convolutional Neural Networks (CNN)

Best for: Image or spectrographic analysis. Pros: Can “see” patterns in vibration spectrograms or thermal images. Cons: Requires massive datasets. Use Case: Analyzing thermal camera feeds for electrical hotspots.

Data Architecture Blueprint

To achieve real-time prediction, you need a robust data pipeline.

Layer 1: Data Acquisition (DAQ)

- Protocol Conversion: Converting proprietary protocol (Modbus, Profinet, Ethernet/IP) into a unified format (JSON/MQTT).

- Frequency: Vibration sensors might sample at 10kHz, but you only need to send summary statistics (RMS, Kurtosis, Peak-to-Peak) to the cloud every minute to save bandwidth.

Layer 2: Edge Processing (The “First Filter”)

- Filtering: Removing noise (e.g., vibration caused by a forklift driving by).

- Feature Extraction: Turning raw signals into meaningful data points.

- Local Inference: Running the lightweight model on the gateway to shut down a machine in milliseconds if a critical safety threshold is breached.

Layer 3: Cloud / On-Prem Historian

- Storage: Time-series databases (InfluxDB, TimescaleDB) are essential for handling high-velocity sensor data.

- Contextualization: Merging sensor data with maintenance logs (SAP PM) to label the data (i.e., telling the model “This vibration spike was a bearing failure”).

Layer 4: Visualization & Action

- Dashboards: PowerBI or Grafana panels for plant managers.

- Alerts: PagerDuty or SMS integration for technicians.

- Control: Writing back to the PLC to automatically derate a machine (slow it down) to preserve it until the next shift.

Real-World Case Studies

Automotive: 30% Down-time Reduction

A major auto parts manufacturer installed vibration sensors on their CNC machines.

- Problem: Spindle failures were causing 4-hour stoppages twice a month.

- Solution: AI detected spindle vibration anomalies 48 hours in advance.

- Result: Maintenance teams scheduled replacements during shift changes. Unplanned downtime dropped by 30%.

Food & Beverage: $40K/Month Savings

An industrial bakery faced frequent breakdowns of their main mixer.

- Problem: Gearbox failures ruined batches of dough ($5K per incident).

- Solution: Current monitoring detected increased load on the motor—a proxy for gearbox friction.

- Result: Prevented 8 breakdowns in year 1, saving $40k/month in waste and downtime.

Implementation Guide: 4 Steps to Deployment

Step 1: Criticality Analysis (Week 1)

Don’t censor everything. Focus on “Critical Assets”—machines that:

- Bottle-neck production if they stop.

- Have high repair costs.

- Have a history of failure. Tip: Start with your top 5-10 assets.

Step 2: Data Audit & Sensor Retrofit (Weeks 2-3)

- Check: Do you have existing data? (Historical logs).

- Install: If not, retrofit continuous monitoring sensors (IoT wireless sensors are quick to deploy).

- Connect: Bridge the data to the AgenixHub platform via secure gateway.

Step 3: Baseline & Learning (Weeks 4-8)

- Training: Let the system run to establish a baseline of “normal” behavior.

- Thresholds: Set initial alert thresholds based on ISO standards (e.g., ISO 10816 for vibration).

Step 4: Active Monitoring (Month 3+)

- Alerts: Maintenance teams receive email/SMS alerts when anomalies occur.

- Verification: Technicians inspect flagged machines to confirm the diagnosis (reinforcing the AI loop).

Failure Mode & Effects Analysis (FMEA) with AI

AI doesn’t just predict that a failure will occur; it helps diagnose why. Here is how AI enhances standard FMEA:

| Component | Failure Mode | Traditional Detection | AI Detection method | lead Time gained |

|---|---|---|---|---|

| Ball Bearing | Inner Race Spalling | Audible Noise / Heat | Vibration Spectral Analysis (High Freq) | 2-4 Weeks |

| V-Belt | Slippage / Wear | Visual Inspection | Stroboscopic RPM vs Motor RPM mismatch | 1-3 Weeks |

| Gearbox | Gear Tooth Crack | Oil Debris Analysis | Acoustic Emission Transients | 3-6 Weeks |

| Motor | Stator Winding Short | Breaker Trip (Too late) | Motor Current Signature Analysis (MCSA) | 1-2 Weeks |

| Pump | Cavitation | Flow drop / Noise | Dynamic Pressure variances | Real-time |

Troubleshooting Your PdM Deployment

Even the best systems face challenges. Here is how to solve common implementation blockers.

Challenge 1: “The AI is generating too many alerts.”

Diagnosis: Thresholds are too tight, or the model hasn’t seen enough “normal” operating states (e.g., product changeovers). Fix: Implement Context-Aware Thresholds. Train the model to recognize “Changeover Mode” or “Cleaning Mode” so it suppresses alerts during these known transient states.

Challenge 2: “The sensors keep disconnecting.”

Diagnosis: Industrial environments are Faraday cages full of metal and electromagnetic interference (EMI). Fix:

- Switch from Wi-Fi to LoRaWAN or Sub-1GHz mesh networks which penetrate concrete/metal better.

- Use wired sensors for critical assets inside heavy shielding.

- Add repeaters/gateways closer to the assets.

Challenge 3: “We predicted the failure, but the part wasn’t in stock.”

Diagnosis: The disconnect between Operations (Maintenance) and Procurement. Fix: Integrate the PdM platform with your ERP (SAP/Oracle). Configure the system to automatically trigger a purchase requisition when a failure probability exceeds 75% and RUL is < 4 weeks.

Regulatory & Compliance Benefits

Predictive maintenance isn’t just about efficiency; it’s a compliance tool.

ISO 55000 (Asset Management)

AI provides the documented “decision-making framework” required by ISO 55001, proving that maintenance activities are data-driven rather than ad-hoc.

OSHA / EHS

By reducing emergency repairs, you reduce risk. “Rush jobs” are 3x more likely to result in injury than planned work. PdM allows all work to be planned, permitted, and risk-assessed.

FDA / GMP (Pharma & Food)

For regulated industries, proving that equipment was operating within validated parameters is critical. AI logs provide an immutable audit trail of equipment health for every batch produced.

Calculate the Cost of Your Downtime

Use this calculator to see how much

Learn more about AI implementation costs. reactive maintenance is costing your business and the potential savings from a Predictive Maintenance program.

Estimate Your Potential Savings

Based on industry benchmarks and typical deployment scenarios. Actual results may vary based on facility size, equipment age, and data readiness.

Frequently Asked Questions

Can AI reduce spare parts inventory costs?

Yes, significantly. By knowing exactly when a part will fail (with 7-14 day advance warning), you can order replacements “just in time” rather than stocking expensive spares “just in case.”

Typical Results:

- Reduce spare parts inventory by 20-30%

- Free up $100K-$500K in working capital for mid-sized facilities

- Eliminate emergency expediting fees (2x-5x normal part cost)

- Improve parts availability from 85% to 95%+ (right parts, right time)

Example: A food processing plant reduced bearing inventory from 200 SKUs to 120 SKUs while improving equipment uptime. The AI’s accurate failure predictions allowed them to stock only critical fast-moving parts and source slow-movers on demand.

What happens if I don’t have historical failure data?

You can still start—and quickly build value. We use three approaches for new or data-sparse environments:

- Anomaly Detection Models: These don’t need failure history. They learn what “healthy” operation looks like and flag deviations. Catches 70-80% of issues.

- Transfer Learning: We apply models trained on similar equipment types (same motor size, bearing type, operating conditions) and fine-tune them on your data within 4-8 weeks.

- Hybrid Approach: Start with vibration thresholds from ISO standards (ISO 10816) while the AI learns your specific patterns.

**Timeline

Learn more about how long AI implementation typically takes.**: Even with zero history, you’ll get valuable alerts in Week 1 and high-accuracy predictions by Month 3.

How quickly does predictive maintenance pay for itself?

Typically 3-9 months for pilot deployments, often faster.

The ROI acceleration comes from preventing just ONE major failure:

- Single Line Stoppage: $50K-$500K in lost production (automotive, pharma, food)

- Emergency Repair Costs: 3x-10x planned maintenance cost

- Expedited Parts: 2x-5x normal part cost for overnight shipping

Real Example: A beverage bottling plant invested $85K in a PdM pilot. Month 4, the AI predicted a gearbox failure on their main filler line 11 days in advance. Scheduled replacement during a planned weekend shutdown cost $18K. Emergency failure would have cost $350K (lost production + emergency repair). ROI achieved in one prediction.

Is this only for large enterprises?

No—small and mid-sized manufacturers see the fastest ROI.

Why SMMs benefit more:

- Lean Operations: Less redundancy means each asset is more critical

- Lower Tolerance for Downtime: Can’t afford backup production lines

- Smaller Maintenance Teams: AI multiplies limited staff effectiveness

- Technology Democratization: Wireless IoT and SaaS pricing make enterprise-grade PdM affordable ($30K-$100K vs. $500K+ in the past)

Sweet Spot: 50-500 employee manufacturing facilities with $20M-$200M revenue see 200-600% ROI in Year 1.

How accurate are the predictions?

85-95% for well-instrumented critical assets.

Accuracy depends on three factors:

- Data Quality: Good sensor placement and calibration → higher accuracy

- Operating Consistency: Stable process conditions → better predictions than highly variable processes

- Failure Type: Gradual degradation (bearings, belts) = 90-95% accuracy. Sudden failures (electrical faults) = 70-80% accuracy

False Positive Management: Modern systems aim for less than 10% false positives. You’d rather investigate 10 alerts (9 real, 1 false) than miss 1 critical failure.

Can PdM integrate with my existing CMMS?

Yes, and this integration is critical for ROI.

AgenixHub integrates with:

- SAP PM (Plant Maintenance)

- IBM Maximo

- Infor EAM

- eMaint

- Fiix

- Any CMMS with REST API

Workflow Automation:

- AI predicts failure → 2. Generates work order in CMMS → 3. Assigns to technician → 4. Prepares parts list → 5. Schedules during planned downtime → 6. Technician confirms completion → 7. AI learns from outcome

This closed-loop integration eliminates manual data entry and ensures predictions drive action, not just alerts.

What about legacy equipment without digital interfaces?

Retrofitting is straightforward and cost-effective.

Sensor Options:

- Clamp-on Current Sensors: Monitor motor electrical signature without wiring changes ($150-$300)

- Magnetic-Mount Vibration Sensors: Attach to motor/bearing housings, no drilling required ($200-$500)

- Wireless Temperature Strips: Battery-powered, last 3-5 years ($50-$150)

- Acoustic Sensors: Non-contact ultrasonic monitoring ($300-$600)

Total Retrofit Cost: $500-$1,500 per legacy asset. Payback from first prevented failure.

How does AI handle varying operating conditions?

Contextual learning and normalization.

Good PdM systems account for:

- Load Variations: Motor vibration changes with load—AI normalizes readings to % of rated capacity

- Temperature: Ambient temperature affects sensor readings—AI applies temperature compensation

- Production Schedules: Different vibration signatures during startup, steady-state, and shutdown—AI recognizes operational mode

- Environmental Factors: Humidity, altitude, and seasonal variations are factored into baselines

Advanced Feature: “Digital Twin” models simulate equipment behavior under different conditions, improving prediction accuracy for variable processes by 15-25%.

What happens during planned shutdowns?

Perfect opportunity for targeted inspections.

The AI provides a prioritized inspection list:

- Red Alerts: Equipment predicted to fail before next shutdown—replace immediately

- Yellow Warnings: Degrading components—inspect and decide (replace now or monitor closely)

- Green Status: Healthy equipment—skip inspection, focus resources elsewhere

This risk-based approach cuts shutdown inspection time by 30-50% while improving thoroughness.

How does this affect my warranty coverage?

It usually helps it. OEM warranties often require “proper maintenance.” AI logs provide irrefutable proof that you operated the machine within its design limits and performed maintenance exactly when needed. Some OEMs now offer “Performance Warranties” where they monitor the machine remotely and guarantee uptime.

What skill sets do I need to hire?

You likely don’t need to hire anyone. Modern platforms are designed for Reliability Engineers and Maintenance Techs, not Data Scientists.

- Technicians need to learn how to mount sensors and interpret the dashboard (Training: 1-2 days).

- Engineers need to understand FMEA and how to set alert priorities.

- IT needs to support network security and firewall rules.

How secure is the sensor data?

Extremely secure.

- Encryption: Data is encrypted AES-256 at rest and TLS 1.3 in transit.

- One-Way Traffic: Sensors typically communicate out-bound only. They cannot process incoming commands, making them impossible to “hack” to control the machine.

- Isolation: The IoT network is usually VLAN-segmented from the corporate business network and the Control System (OT) network.

Can I monitor mobile assets (forklifts, AGVs)?

Yes. Cellular-connected (LTE-M / NB-IoT) sensors are perfect for moving assets. Use Cases:

- Battery Health: Predicting battery degradation to optimize charging cycles.

- Impact Detection: Detecting collisions or abuse.

- Wheel/Tire Wear: Monitoring vibration to detect wheel flats.

What is the environmental impact (ESG)?

PdM is a major sustainability driver.

- Energy: Well-maintained motors use 5-10% less electricity.

- Waste: Preventing catastrophic failure saves the embodied carbon of the destroyed machine and the scrapped product.

- Oil/Lubricants: Changing oil based on condition rather than schedule reduces oil consumption by 30-50%.

How do I justify the cost to the CFO?

Speak “Risk” and “Cash Flow”, not “Vibration”.

- Don’t say: “We need to detect bearing frequencies.”

- Do say: “This investment mitigates the $2M risk of a main line outage and frees up $200K in spare parts cash flow in Year 1.”

Use our ROI Calculator to generate these exact numbers.

Key Takeaways

- Stop Reacting: Reactive maintenance is the most expensive way to run a factory (3-10x cost of planned work).

- Start with Critical Assets: Don’t sensor the coffee machine. Focus on the bottleneck assets that drive revenue.

- Data is Key: The quality of your prediction depends on the quality of your sensor data.

Summary

In summary, manufacturing predictive maintenance is a transformative strategy that shifts operations from reactive firefighting to proactive management. By leveraging AI to predict failures, manufacturers can significantly reduce downtime, lower maintenance costs, and extend the lifespan of their most valuable assets.

Recommended Follow-up:

Ready to eliminate unplanned downtime? Contact AgenixHub to deploy a rapid 30-day PdM pilot.

Don’t wait for your machines to break. Deploy AI predictive maintenance with AgenixHub today.