Manufacturing Supply Chain AI 2025

AI demand forecasting achieves 85-95% accuracy vs. 60-70% traditional methods. Learn supply chain optimization strategies delivering $4-10M working capital improvements.

Manufacturing Supply Chain Optimization: AI Strategies for 2025

What is Manufacturing Supply Chain Optimization?

Manufacturing supply chain optimization refers to the systematic application of artificial intelligence and machine learning to improve efficiency, reduce costs, and enhance resilience across the entire value chain. It describes how organizations use predictive analytics to forecast demand, optimize inventory levels, coordinate logistics, and manage supplier relationships in response to dynamic market conditions and global disruptions.

Quick Answer

AI Supply Chain Optimization uses machine learning to predict demand, optimize inventory levels, and route logistics in real-time. By moving from historical “averages” to predictive “signals,” manufacturers can reduce inventory holding costs by 20-40%, improve demand forecasting accuracy to 95%, and cut stockouts by half.

In a world where disruptions like the Red Sea crisis cost $6 billion per week, AI provides the dynamic resilience needed to protect margins as part of a comprehensive Manufacturing AI Implementation Strategy.

Quick Facts

- Demand Forecasting Accuracy: 85-95% (vs 60-70% traditional)

- Inventory Carrying Cost Reduction: 20-40%

- Logistics Cost Reduction: ~15%

- Stockout Reduction: Up to 50%

- Working Capital Improvement: $4M-$10M per $100M revenue

Key Questions

Why is AI required for modern supply chain management?

Traditional Excel-based forecasting cannot account for the rapid lead-time variability and global disruptions seen in 2025. AI analyzes non-linear relationships and external signals (weather, trade data) to provide a more accurate Demand Signal.

How does AI help reduce manufacturing inventory?

AI uses Multi-Echelon Inventory Optimization (MEIO) to balance stock levels across entire networks, ensuring parts are available where needed without overstocking at every location.

Can AI predict supply chain disruptions like port strikes?

While AI cannot predict a discrete “Black Swan” event, it detects the ripple effects (shipping delays, volume changes) within hours, allowing for immediate recalculation of safety stock and routing.

The Disruption Landscape 2024-2025

The “Just-in-Time” model is broken. “Just-in-Case” is the new reality. Recent global events have exposed the fragility of lean supply chains:

1. The Red Sea Crisis

Attacks on shipping lanes have forced vessels to reroute around Africa, adding 10-14 days to lead times and increasing fuel costs by 40%.

- Impact: $6 Billion per week in delayed trade.

- Result: Manufacturers relying on static lead times in their ERPs faced stockouts of critical components.

2. Infrastructure Failures (Baltimore Bridge)

The collapse of the Key Bridge disrupted the 9th busiest US port.

- Daily Impact: $12 Million in blocked logistics.

- Ripple Effect: Auto manufacturers (Mazda, Mercedes-Benz) had to reroute thousands of vehicles overnight.

3. Port Congestion & Labor Strikes

Labor disputes at major hubs (Los Angeles, Rotterdam) have caused freight capacity to decline by 25% during peak seasons.

- Statistic: Companies experience a 45% profit loss over 10 years due to unmitigated supply chain disruptions.

Technical Deep Dive: AI Forecasting Architectures

How do we move from “Gut Feel” to 95% Accuracy? We use specific algorithms for specific data types.

A. DeepAR (Probabilistic Forecasting)

Traditional forecasting gives you a single number: “You will sell 100 units.” DeepAR gives you a probability: “There is an 80% chance you will sell between 90 and 110 units.”

- Why it matters: It allows you to plan safety stock based on uncertainty, not just averages.

- Best for: Erratic demand with high volatility.

B. Facebook Prophet (Trend + Seasonality)

Decomposes time-series data into:

- Trend: Is the market growing?

- Seasonality: Do we sell more in Q4?

- Holidays: Does Chinese New Year shut down our supplier?

- Best for: Products with strong seasonal patterns (e.g., HVAC units, consumer electronics).

C. Graph Neural Networks (GNN)

Maps the supply chain as a “Graph” of nodes (Supplier -> Port -> Warehouse -> Factory).

- Capability: If a node (Port of Shanghai) is blocked, the GNN calculates the propagation delay to every downstream node instantly.

- Best for: Multi-tier supply chain visibility.

Inventory Management: The Silent Cash Killer

Inventory carrying costs often eat 15-35% of the total inventory value annually. If you hold $10M in inventory, you are paying $1.5M - $3.5M just to keep it on the shelf.

The Cost Breakdown

- Capital Cost (10-15%): The interest you pay on the money tied up in stock.

- Storage Cost (5-10%): Warehouse rent, electricity, forklift operations.

- Service Cost (2-5%): Insurance and taxes.

- Risk Cost (5-10%): Obsolescence (parts going out of date) and shrinkage (theft/damage).

The AI Solution: Dynamic Parameter Optimization

AI doesn’t just predict demand; it optimizes the parameters that control your inventory.

- Static Min/Max: “Always reorder when we hit 50 units.” (Fail: Doesn’t account for slower shipping).

- Dynamic Reorder Point: “Lead times just increased by 4 days due to weather; increase reorder point to 65 units immediately.”

Result: Companies using AI Optimization reduce carrying costs by 20-40%, freeing up $4M-$10M in working capital per $100M in revenue.

Common Questions

Why is traditional forecasting failing in 2025?

Traditional forecasting relies on historical sales data (e.g., “What did we sell last year?”), which fails when consumer behavior and geopolitics shift rapidly.

The disruptions of 2024—from the Baltimore Bridge collapse to global tariff changes—proved that history is no longer a reliable predictor of the future. Traditional Excel-based models cannot account for:

- Lead time variability: Shipping times increasing by 14 days overnight.

- External signals: Weather patterns, social media trends, or economic indicators.

- Complexity: Managing thousands of SKUs across multi-echelon networks.

How accurate are the forecasts?

85-95%. Traditional Excel/ERP forecasting typically achieves 60-70% accuracy. AI creates a massive leap by analyzing non-linear relationships (“When oil prices drop AND it rains in April, demand for Product X spikes”).

Can AI predict “Black Swan” events?

No, but it reacts faster than you. AI cannot predict a bridge collapse (Black Swan). However, it can detect the ripple effects (shipping delays, port volume changes) within hours and re-calculate your safety stock requirements immediately. A human team might take weeks to update 5,000 SKUs; AI does it overnight.

Does it integrate with SAP / Oracle?

Yes. We don’t replace your ERP. We treat the ERP as the “System of Record” and the AI as the “System of Intelligence.”

- AI reads sales history and inventory levels from SAP.

- AI calculates the new forecast and safety stock.

- AI writes the new Purchase Requisitions back into SAP for approval.

What is the “Bullwhip Effect” and how do we stop it?

The Bullwhip Effect is when small changes in customer demand cause massive fluctuations upstream. Customer buys 5% more -> Retailer orders 10% more -> Distributor orders 20% more -> Factory produces 40% more. Solution: End-to-End Visibility. By sharing the AI forecast across the tiers (Vendor Managed Inventory), everyone builds to the real demand, not the distorted signal.

How much ROI can I expect?

Learn more about AI implementation costs. Typical ROI is 150-300% in the first year.

- Hard Savings: Inventory reduction (Cash release), lower expedited freight costs.

- Soft Savings: Planner productivity (less time crunching numbers), improved customer satisfaction (OTIF).

- Payback Period: Typically 6-12 months.

What data do I need to start?

Ideally 2-3 years of historical transaction history detailed by:

- Item (SKU)

- Location (Warehouse)

- Customer

- Time (Day/Week) If you have “out of stock” history, that is gold—it tells the AI what you could have sold.

Can it optimize transportation routes?

Yes. AI Logistics engines consider:

- Fuel costs.

- Driver hours (regulations).

- Traffic patterns.

- Delivery windows. It solves the “Vehicle Routing Problem” (VRP) to reduce logistics spend by 15%.

What about “Long Tail” items?

AI loves the Long Tail. Pareto Principle: 20% of items drive 80% of volume. Humans focus on the top 20%. AI can manage the remaining 80% (thousands of slow-moving parts) automatically, ensuring you don’t overstock items that only sell twice a year.

How does it handle new product launches (NPI)?

Clustering and Attribute-Based Modeling. Since the new product has no history, the AI looks at its attributes (Color, Size, Price Point, Category) and finds “Safe Twins”—similar products that launched in the past. It uses their launch curves to predict the new product’s performance.

Is this a one-time project?

No, it’s a continuous capability. Supply chains are living organisms. Suppliers change, lead times drift, customer preferences shift. The AI model retrains itself weekly or monthly to stay in sync with reality.

Deep Dive: AI Capabilities in Supply Chain

1. Dynamic Inventory Optimization

Instead of static “Min/Max” levels reset once a year, AI dynamically adjusts reorder points every day based on:

- Current lead times: “Port of Los Angeles is congested; increase lead time buffer by 4 days.”

- Predicted demand surges: “Heatwave incoming; increase HVAC stock by 15%.”

- Cost of capital: “Interest rates are up; reduce slow-moving stock to free up cash.”

The Math Behind It: Multi-Echelon Optimization

Standard ERPs optimize one location at a time. AI uses Multi-Echelon Inventory Optimization (MEIO). It asks: “Should I hold this spare part at the central distribution center (cheap storage, slow delivery) or at the local regional warehouse (expensive storage, fast delivery)?” Result: It balances the total cost across the entire network, often finding that you can reduce total inventory by 30% while actually increasing service levels.

2. Predictive Logistics & Route Optimization

Goal: Get products where they need to be, faster and cheaper. AI analyzes route efficiency, carrier performance, and fuel costs to:

- Consolidate shipments: Identify that 3 LTL (Less Than Truckload) shipments to the same region can be combined into 1 FTL (Full Truckload) shipment, saving 40%.

- Reroute shipments: “Hurricane predicted in Florida; reroute shipments via Atlanta hub.”

- Carrier Selection: Select carriers based on real-time reliability scores, not just contract price. “Carrier A is cheaper but late 30% of the time. Carrier B is 5% more expensive but 99% on time. Choose Carrier B for this critical order.”

3. Supplier Risk Management 3.0

Traditional risk management is an annual survey. AI Risk Management is a 24/7 radar. It scrapes:

- Financial News: “Supplier X just missed an earnings call.”

- Geopolitical Feeds: “Strike announced at Port of Hamburg.”

- Weather Data: “Typhoon crossing Taiwan shipping lanes.” It combines these into a Risk Score (0-100) for every supplier.

- Alert: “Supplier B in Taiwan is at risk (Score: 85). Switch orders to Supplier C in Mexico immediately.”

- Result: Proactive mitigation before the line stops.

4. The “Digital Supply Chain Twin”

The ultimate maturity level is a Digital Twin. This is a virtual simulation of your entire supply chain. Capability: It allows for “What-If” Scenario Planning.

- Scenario: “What if our primary chip supplier in Taiwan goes offline for 3 months?”

- Simulation: The Twin runs the numbers. “Result: Production stops in 14 days. Revenue risk: $50M. Mitigation: Air freight stock from backup supplier in Germany costs $2M but saves the quarter.”

- Benefit: It turns Crisis Management into Risk Management. You have the plan ready before the disaster happens.

Real-World Impact

Electronics Manufacturer: Inventory Reduction

A mid-sized electronics firm struggled with excess component stock.

- Action: Implemented AI forecasting.

- Result: Reduced inventory levels by 24% while maintaining a 98% service level. Freed up $12M in working capital.

Food & Beverage: Freshness Optimization

A beverage distributor used AI to predict regional flavor preferences.

- Result: Reduced waste (expired product) by 30% and increased on-shelf availability during heatwaves.

Calculate Your Savings

See how much working capital you could free up by optimizing your inventory levels with AI.

Supply Chain AI Savings Estimator

Estimate the financial impact of AI-driven demand forecasting and inventory optimization.

Value of stock currently on hand

Typical range: 20-35%

Roadmap: 3 Steps to a Smarter Supply Chain

Step 1: Clean Your Data (Month 1)

Garbage in, garbage out.

- Consolidate: Get data out of spreadsheets and into a unified data lake.

- Standardize: Ensure SKU naming conventions match across all facilities.

Step 2: Implement Demand Sensing (Month 2-3)

- Deploy: Connect your sales history to the AI engine.

- Enrich: Add external data feeds (holidays, economic indices, competitor pricing).

- Test: Run the AI forecast against last year’s actuals (Backtesting) to prove accuracy.

- Outcome: A “Demand Signal” that is 20-30% more accurate than the sales team’s manual forecast.

Step 3: Sales & Operations Planning (S&OP) Integration (Month 4)

- Align: Bring Operations, Sales, and Finance into a single room (or Zoom).

- Visualize: Use the AI dashboard to show the “One Number” plan.

- Decide: “The AI predicts a 20% surge. Finance, do we have the cash for inventory? Ops, do we have the capacity?”

- Result: Alignment. No more “Sales sold it, but Ops can’t make it.”

Step 4: Automate Replenishment (Month 5-6)

- Trust Phase: Let the AI suggest reorder quantities. The planner reviews and clicks “Approve.”

- Measure: Track how often the planner changes the AI’s suggestion. (Goal: < 10% modifications).

- Automate: Once trust is established, allow the AI to execute low-risk orders (C-Class items) automatically (“Touchless Planning”).

Step 5: Supplier Collaboration (Month 7+)

- Share: Give key suppliers access to a portal showing your consumption forecast.

- Benefit: They can plan their production better, reducing lead times and costs for you.

- VMI: Move to Vendor Managed Inventory where the supplier owns the stock until you consume it.

Frequently Asked Questions

Does AI require replacing my ERP?

No. AI platforms like AgenixHub integrate with your ERP (SAP, Oracle, NetSuite). The ERP executes the transaction; the AI provides the intelligence on what and when to transact.

How does AI handle new product launches without history?

“Clustering” algorithms. The AI analyzes the attributes of the new product (price, category, features) and looks at how similar products performed during their launches to predict the new trajectory.

Can AI help with supply chain sustainability?

Yes. By optimizing truckloads and routes, AI significantly reduces fuel consumption and CO2 emissions. Plus, reducing overproduction is the single best way to minimize waste.

What about data security with suppliers?

Federated Learning. You can train models across your supplier network without actually sharing proprietary sales data. Each party keeps their data private, but the “learnings” are shared to optimize the whole chain.

Vendor Selection Checklist for Supply Chain AI

Choosing the right partner is critical. Do not just buy software; buy a capability.

1. Data Ingestion Capabilities

- ERP Adapters: Does it have pre-built connectors for SAP, Oracle, NetSuite?

- External Data: Does it automatically ingest weather, economic, and geopolitical feeds?

- Latency: Can it process live sales data sales hourly, or only daily?

2. Algorithmic Transparency

- Explainability: Can the system explain why it predicts a 20% spike? (Avoid “Black Box” models).

- Customizability: Can we adjust parameters (e.g., service level targets) by SKU category?

- Backtesting: Can the vendor prove accuracy by running their model on your past data?

3. Implementation Speed

- Time-to-Value: Is it a 12-month consulting project or a 6-week software deployment?

- Scalability: Can we start with one region and roll out globally?

4. Support & Training

- Planner Training: Do they train your demand planners to become “exception managers”?

- 24/7 Support: Is support available during your critical planning cycles?

Why AgenixHub? We focus on Speed to Value. Our pre-built ERP connectors and “Glass Box” AI models mean you see results in weeks, not years. We don’t just predict; we explain.

4. Key Takeaways

- Cash is King: Supply chain AI is primarily a “Cash Release” machine—freeing up millions from warehouse shelves.

- Agility Wins: The goal isn’t just accuracy; it’s the ability to pivot instantly when the next disruption hits.

- Start with Forecasting: It’s the highest ROI entry point. Fix the input signal, and everything downstream improves.

Summary

In summary, manufacturing supply chain optimization is no longer optional in the volatile global market of 2025. By implementing AI-driven demand forecasting, inventory optimization, and predictive logistics, manufacturers can protect themselves from disruptions while freeing up millions in working capital.

Recommended Follow-up:

- Manufacturing AI Implementation Guide

- Manufacturing Quality Control AI

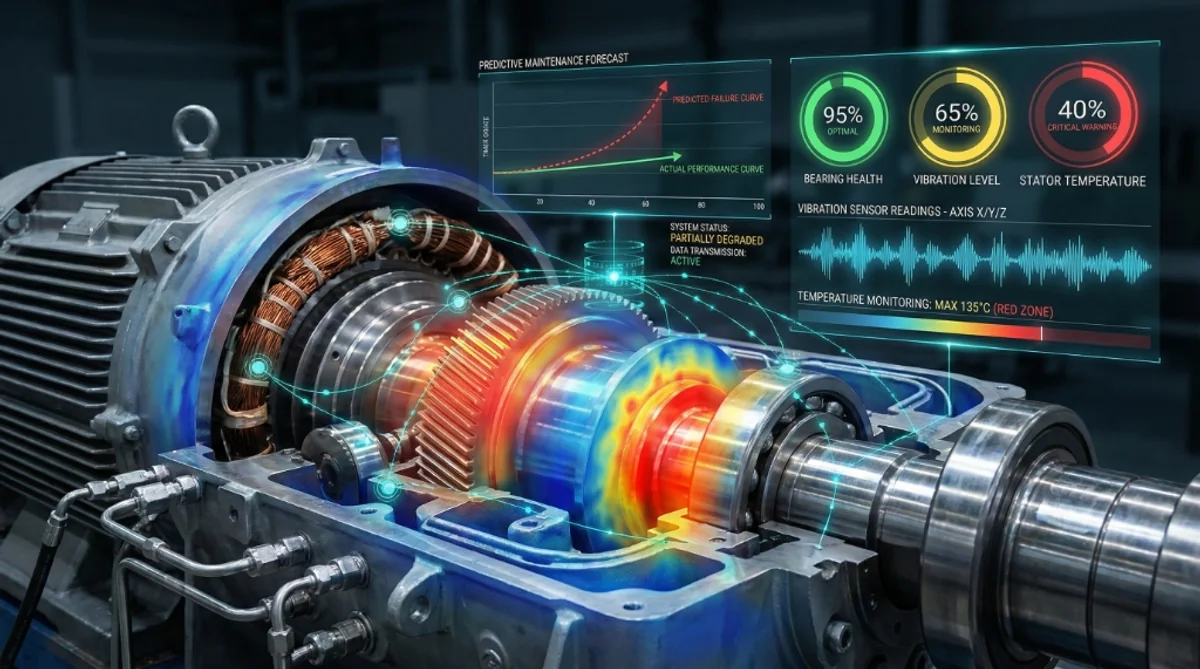

- Manufacturing Predictive Maintenance

Stop guessing and start predicting. Contact AgenixHub to audit your supply chain data readiness.

Don’t let supply chain shocks paralyze your production. Deploy AI optimization with AgenixHub today.