Manufacturing AI Guide 2025

Learn how to implement AI in manufacturing with a proven roadmap. Discover ROI timelines (90 days), costs ($25K-$100K), and strategies for predictive maintenance and quality control.

Manufacturing AI Implementation Guide: How to Get Started in 2025?

What is Manufacturing AI Implementation?

Manufacturing AI implementation refers to the deployment of machine learning models and artificial intelligence technologies to optimize production processes, improve product quality, and enhance predictive maintenance on the shop floor. It describes how organizations integrate AI with existing Industrial IoT, Manufacturing Execution Systems, and Enterprise Resource Planning systems to transform raw operational data into actionable insights for reducing downtime, detecting defects, optimizing energy consumption, and improving supply chain efficiency.

Quick Answer

Manufacturing AI implementation involves deploying machine learning models to optimize production, quality, and maintenance. In 2025, modern platforms like AgenixHub enable you to bypass multi-year digital transformations, launching targeted AI solutions in just 2-4 weeks with costs ranging from $25K to $100K. The focus is on specific, high-ROI use cases like predictive maintenance and visual inspection, which can deliver measurable returns in as little as 90 days.

You don’t need to overhaul your entire factory to start. By integrating with existing MES and ERP systems through pre-built connectors, you can unlock efficiency gains of 30-50% without significant downtime or infrastructure replacement. Achieve faster Manufacturing AI ROI by prioritizing high-impact use cases.

Quick Facts

- Implementation Speed: 2-4 weeks (AgenixHub)

- Typical Costs: $25K-$100K (vs $500K+ traditional)

- Measured ROI Timeline: 90 days to 6 months

- Efficiency Gains: 30-50%

- Success Rate: 3x higher with “crawl, walk, run” approach

Key Questions

How long does it take to implement AI in a factory?

Modern AI platforms allow for initial pilot deployment in just 2-4 weeks, with full-scale ROI typically realized within 90 to 180 days.

Do I need to replace my existing MES or ERP for AI?

No, AI platforms like AgenixHub integrate with existing systems via standard protocols (OPC UA, MQTT) to leverage current data without a total system overhaul.

What are the main benefits of AI in manufacturing?

Key benefits include a 35-45% reduction in unplanned downtime, 99.8% defect detection accuracy, and up to 30% reduction in annual energy costs.

Quick Answer

Manufacturing AI implementation involves deploying machine learning models to optimize production, quality, and maintenance. In 2025, modern platforms like AgenixHub enable you to bypass multi-year digital transformations, launching targeted AI solutions in just 2-4 weeks with costs ranging from $25K to $100K. The focus is on specific, high-ROI use cases like predictive maintenance and visual inspection, which can deliver measurable returns in as little as 90 days.

You don’t need to overhaul your entire factory to start. By integrating with existing MES and ERP systems through pre-built connectors, you can unlock efficiency gains of 30-50% without significant downtime or infrastructure replacement. Achieve faster Manufacturing AI ROI by prioritizing high-impact use cases.

Common Questions

Why is AI implementation critical for manufacturers right now?

Manufacturers implementing AI today are seeing 200-500% ROI and reducing unplanned downtime by up to 45%.

The manufacturing landscape in 2025 is defined by increasing cost pressures, labor shortages, and supply chain volatility. AI provides the operational agility to withstand these shocks. Specifically:

- Cost Reduction: Predictive maintenance alone saves $280B annually industry-wide.

- Labor augmentation: AI automates repetitive visual inspections, freeing up your skilled workers for complex problem-solving.

- Competitive Advantage: With 41% of manufacturers prioritizing automation, those who delay risk falling behind in both efficiency and pricing

Learn more about AI implementation costs. power.

How much does it actually cost to implement AI?

Modern, modular AI implementations typically cost between $25,000 and $100,000 for initial deployment, compared to $500K-$5M for traditional consulting-led projects.

The old model of “rip-and-replace” is dead. You can now leverage:

- Cloud-hybrid models: Offload heavy training to the cloud while running inference locally (or completely on-prem).

- SaaS pricing: Pay for the capabilities you use rather than massive upfront CAPEX.

- Pre-built agents: Use “off-the-shelf” models for common tasks like safety monitoring or defect detection, reducing custom development costs by 70%.

What is the typical ROI timeline?

You should expect to see measurable ROI within 3 to 6 months for focused use cases like quality control and predictive maintenance.

Projecting a multi-year payback period is often a sign of scope creep.

- 90 Days: Initial pilot results (e.g., accuracy of defect detection).

- 6 Months: Validated financial savings (e.g., reduced scrap rate, energy savings).

- 12 Months: Full scale deployment ROI of 2-5x.

Key Point: AgenixHub deployments are designed to demonstrate value in the first 90 days.

Core AI Solutions for Manufacturing

You likely have dozens of potential use cases. Where should you start? The data points to four high-impact areas where AI delivers the fastest value.

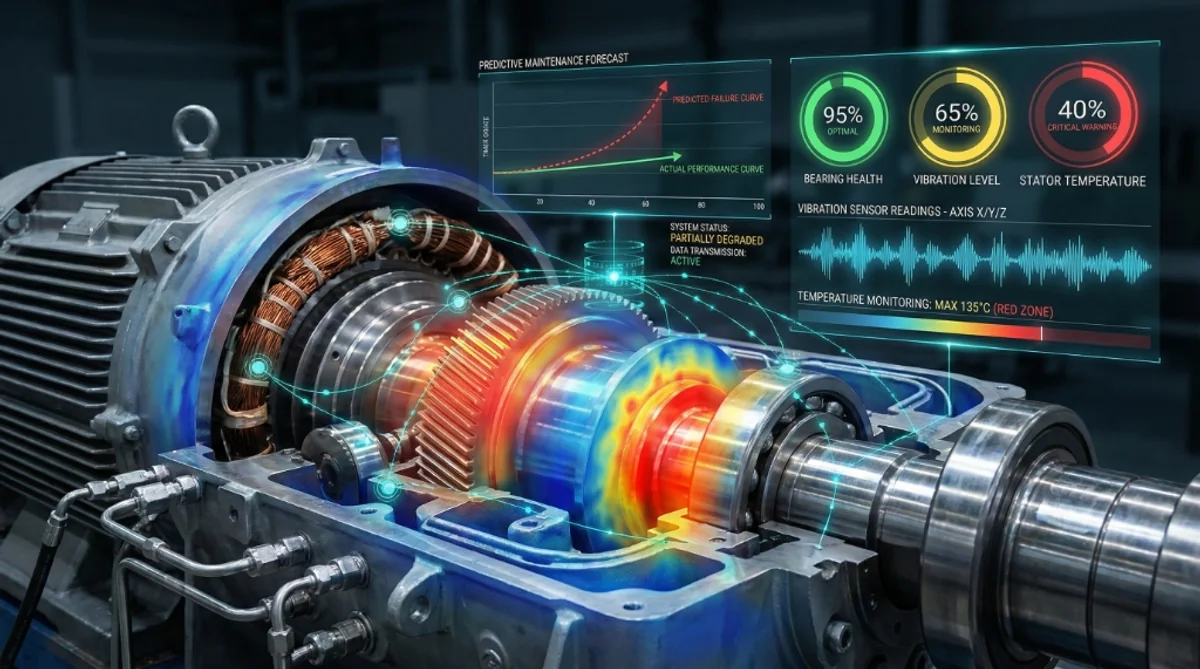

1. Predictive Maintenance

Goal: Stop fixing machines after they break.

AI analyzes sensor data (vibration, heat, pressure) to predict failure before it happens. The technology has matured to the point where it’s no longer experimental—it’s a competitive necessity.

How it Works:

- Sensors continuously monitor equipment health in real-time

- Machine learning models detect anomalies that precede failures by days or weeks

- Maintenance teams receive alerts with predicted failure dates and root causes

- Repairs are scheduled during planned downtime, not emergency shutdowns

Business Impact:

- Impact: 35-45% reduction in unplanned downtime

- Accuracy: 85-95% failure prediction accuracy (validated across thousands of deployments)

- Cost Savings: 25-40% reduction in maintenance costs

- Asset Life: 20-30% extension of equipment lifespan

Real-World Example: A major automotive manufacturer implemented predictive maintenance on their assembly line robots. The system detected bearing wear patterns 14 days before failure, allowing the team to schedule replacements during the weekend shift change. This single intervention prevented a catastrophic line stoppage that would have cost $2.3M in lost production. The annual savings from predictive maintenance exceeded $12M across their facility.

2. Quality Control & Visual Inspection

Goal: Catch 100% of defects without slowing the line.

Human inspectors are excellent at many tasks, but repetitive visual inspection isn’t one of them. After just two hours, attention drops significantly due to fatigue. Computer vision systems inspect parts in real-time, detecting microscopic flaws faster and more consistently than the best human inspectors.

The Technology:

- High-resolution industrial cameras capture images at line speed (up to 200 parts/minute)

- Deep learning models trained on thousands of defect examples

- Edge computing enables millisecond inference times

- Automated sorting mechanisms remove defective parts without stopping production

Business Impact:

- Defect Detection: 99.8% accuracy vs. 70-85% for human inspection

- Waste Reduction: 30-45% reduction in scrap and rework costs

- Consistency: 100% inspection coverage (humans typically sample 10-20%)

- Speed: No impact on production throughput

- Labor: Frees inspectors for root cause analysis instead of repetitive checking

Real-World Example: A European electronics manufacturer struggled with PCB solder joint quality. Human inspection caught only 75% of defects, leading to field failures and warranty claims costing €800K annually. After implementing AgenixHub’s visual inspection AI, defect detection improved to 99.2%, warranty claims dropped by 85%, and the system paid for itself in just 6 months. Annual savings now exceed €450K per facility.

3. Energy Optimization

Goal: Cut carbon and costs simultaneously.

Energy typically represents 15-30% of total manufacturing costs. AI optimizes when and how energy is consumed across your facility.

How AI Delivers Energy Savings:

- Demand Response: AI shifts energy-intensive processes to off-peak hours when electricity rates are 40-60% lower

- HVAC Optimization: Smart climate control reduces heating/cooling costs by 25-35% by predicting thermal loads

- Equipment Scheduling: Run equipment at optimal efficiency points, avoiding energy waste from partial loads

- Peak Shaving: Reduce demand charges by intelligently staggering machine startup sequences

Measured Impact:

- Energy Cost Reduction: 12-30% savings on annual utility bills

- Carbon Footprint: Direct reduction of 14,000-28,000 kg CO₂ per facility annually

- Sustainability Compliance: Meet Scope 1 & 2 emission targets required by investors and customers

- Equipment Longevity: Optimized operation reduces thermal stress, extending asset life 15-20%

Real-World Example: Google’s DeepMind reduced data center cooling energy by 40% using similar AI techniques. Manufacturers applying this to production environments see 12-18 month ROI on energy optimization projects.

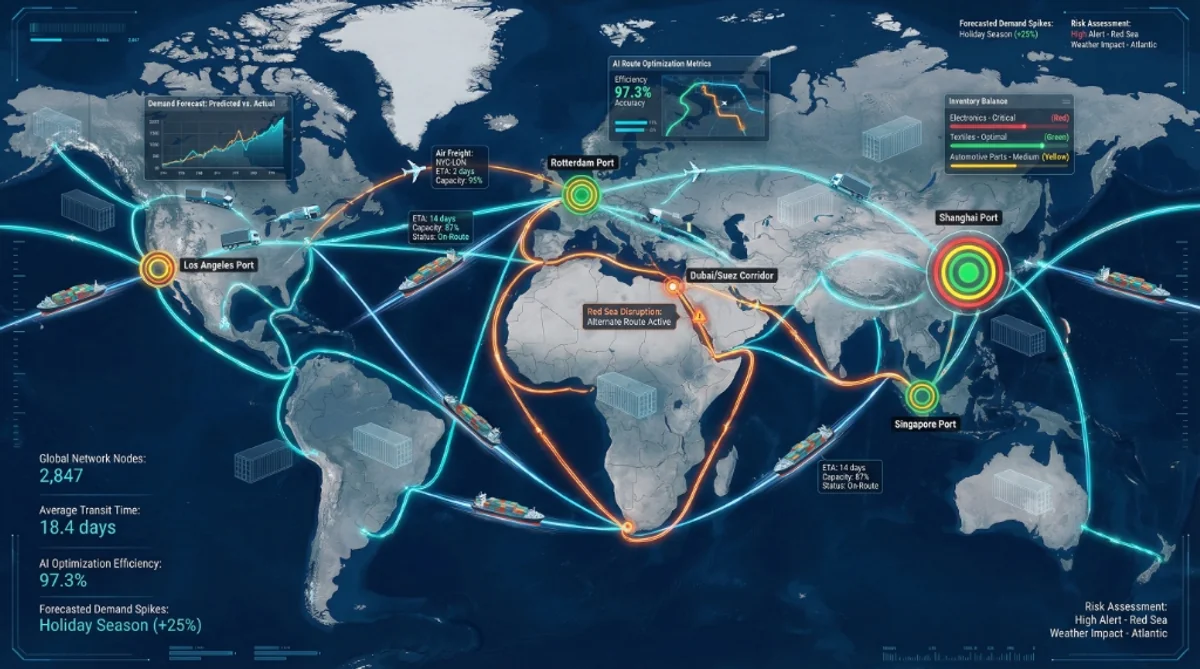

4. Supply Chain Optimization

Goal: Know what you need before you need it.

Supply chain disruptions cost manufacturers billions annually. AI transforms reactive planning into predictive orchestration.

AI Capabilities:

- Demand Sensing: Analyzes point-of-sale data, weather patterns, economic indicators, and social media trends to forecast demand with 85-95% accuracy

- Inventory Optimization: Dynamically adjusts safety stock levels based on real-time lead time variability and demand volatility

- Supplier Risk Scoring: Monitors news, financial reports, and shipping data to predict supplier disruptions before they impact production

- Route Optimization: AI logistics engines reduce transportation costs 10-15% by optimizing for fuel, time, and carbon simultaneously

Business Impact:

- Working Capital: Free up $4M-$10M per $100M revenue by reducing excess inventory 20-50%

- Stockout Reduction: Improve service levels from 85% to 98% while carrying less stock

- Supply Chain Resilience: Receive alerts 7-14 days before potential disruptions (port congestion, supplier issues)

- Planning Efficiency: Reduce planning cycle time from days to hours with AI-assisted S&OP

Case Study: A mid-sized electronics manufacturer reduced inventory by 28% while improving on-time delivery from 82% to 96%. The AI detected a semiconductor shortage risk 3 weeks early, allowing them to secure alternative suppliers while competitors faced production stops.

Calculate Your Potential Savings

Don’t just take our word for it. Use this calculator to estimate the annualized value of implementing AI in your specific facility.

Estimate Your Potential Savings

Based on industry benchmarks and typical deployment scenarios. Actual results may vary based on facility size, equipment age, and data readiness.

Implementation Roadmap: How to Deploy AI in 4 Steps

Implementing AI shouldn’t feel like a science experiment. Follow this structured approach to ensure success.

Step 1: Assessment & Data Readiness (Weeks 1-2)

Summary: Identify your “low hanging fruit” and verify data availability.

- Audit: Which machines cause the most downtime? Where is scrap highest?

- Data Check: Do you have 3-6 months of historical data (logs, sensor readings)?

- Infrastructure: Can we tap into your MES/SCADA? (AgenixHub connects to 95% of standard industrial protocols).

Step 2: Pilot Deployment (Weeks 3-6)

Summary: Prove value on a single line or asset.

- Scope: Deploy ONE solution (e.g., predictive maintenance on the primary conveyor).

- Integration: Connect sensors/cameras without disrupting production.

- Training: Train the model on your specific “good” vs “bad” data.

Step 3: Validation & Optimization (Weeks 7-12)

Summary: Tune the system for maximum accuracy.

- Human-in-the-Loop: Operators review AI flags to confirm accuracy (e.g., “Yes, that was a scratch”).

- Tuning: Adjust sensitivity to balance false positives vs. misses.

- ROI Calculation: Measure actual savings against the baseline from Step 1.

Step 4: Scale & Production (Month 4+)

Summary: Roll out to the rest of the facility.

- Replication: Copy the tested model to similar assets.

- Governance: Establish standard operating procedures (SOPs) for AI alerts.

- Continuous Learning: The system keeps getting smarter as it sees more data.

Comparing Approaches: Traditional vs. Modern AI

| Aspect | Traditional Implementation | Modern AI Platform (AgenixHub) |

|---|---|---|

| Timeline | 6-18 months | 2-4 weeks |

| Cost | $500K - $5M (High CAPEX) | $25K - $100K (Flexible) |

| Infrastructure | Massive cloud dependencies | On-prem/Hybrid capable |

| Expertise | Requires army of data scientists | Designed for manufacturing engineers |

| Data Privacy | Data often leaves premise | Air-gapped / Private AI options |

Recommendation: For most mid-to-large manufacturers, the agility and privacy of a modern platform like AgenixHub significantly outweigh the heavy lift of a custom, consulting-led build.

Implementation Checklist: Your 90-Day Roadmap

Use this checklist to track your AI implementation journey from assessment to production:

Weeks 1-2: Foundation

- Stakeholder Alignment: Secure executive sponsorship and create cross-functional team (Operations, IT, Finance)

- Use Case Prioritization: Identify top 3 pain points with highest financial impact

- Data Audit: Assess availability and quality of historical data (sensor logs, production records, maintenance history)

- Infrastructure Review: Evaluate network connectivity, data storage capacity, and edge computing requirements

- Budget Approval: Secure $25K-$100K for pilot phase

Weeks 3-6: Pilot Development

- Data Pipeline: Establish secure data connections to critical assets

- Platform Setup: Deploy AgenixHub instance (cloud, hybrid, or on-premises)

- Model Training: Train AI models on your specific equipment and processes

- User Interface: Configure dashboards for plant managers and maintenance teams

- Alert Thresholds: Set initial alert levels based on OEM specifications and historical baselines

Weeks 7-10: Shadow Mode Testing

- Parallel Operation: Run AI predictions alongside existing processes without automated actions

- Accuracy Validation: Compare AI predictions to actual outcomes (target: >85% accuracy)

- False Positive Tuning: Adjust sensitivity to minimize alert fatigue

- User Training: Educate maintenance teams on interpreting AI insights

- Integration Testing: Verify data flows from sensors through to work order systems

Weeks 11-12: Production Launch

- Go-Live Authorization: Final approval from operations and IT leadership

- Automated Actions: Enable AI to trigger work orders for high-confidence predictions

- Performance Monitoring: Track KPIs daily (uptime improvement, maintenance cost reduction)

- Continuous Feedback: Gather user feedback and refine workflows

- ROI Measurement: Calculate actual savings vs. baseline

Month 4+: Scale & Optimize

- Expand Coverage: Replicate successful models to additional assets

- Advanced Use Cases: Layer on quality control, energy optimization, or supply chain features

- Model Retraining: Update AI models quarterly with new data

- Executive Reporting: Monthly ROI dashboards showing cumulative impact

Risk Mitigation: Common Pitfalls & Solutions

Pitfall 1: “Boiling the Ocean”

Problem: Trying to implement AI across every process simultaneously. Solution: Start with ONE critical asset or production line. Prove value in 90 days, then scale. The “crawl, walk, run” approach has a 3x higher success rate than big-bang implementations.

Pitfall 2: Data Quality Issues

Problem: AI performance suffers when trained on incomplete or noisy data. Solution: Invest in data cleaning during Weeks 1-2. Even 80% data completeness can yield valuable insights. Use “anomaly detection” approaches that don’t require perfect historical labels.

Pitfall 3: Lack of Buy-In from Operators

Problem: Shop floor teams resist using AI tools they don’t understand or trust. Solution: Involve maintenance technicians and operators from Day 1. Frame AI as “their assistant” not “their replacement.” Show them how AI frees them from firefighting to focus on root cause analysis.

Pitfall 4: Unrealistic ROI Expectations

Problem: Expecting 10x returns in the first month. Solution: Set realistic milestones. Month 1: System operational. Month 3: First prevented failure. Month 6: Measurable cost savings. Month 12: Full ROI achieved.

Pitfall 5: Vendor Lock-In

Problem: Choosing a platform that traps your data or requires expensive proprietary hardware. Solution: Select platforms with open APIs, standard protocols (OPC UA, MQTT), and flexible deployment options (cloud, on-prem, or hybrid).

ROI Breakdown: Where the Money Comes From

Understanding the sources of ROI helps you measure and communicate value to stakeholders.

Direct Cost Savings (60% of ROI)

- Emergency Maintenance Reduction: $50K-$200K per incident avoided

- Spare Parts Optimization: 20-30% reduction in inventory carrying costs

- Energy Efficiency: $100K-$500K annual savings from optimized consumption

- Scrap/Rework Reduction: 30-45% decrease in material waste

Productivity Gains (30% of ROI)

- Increased Uptime: 35-45% reduction in unplanned downtime = more production hours

- Faster Changeovers: AI-optimized setup procedures reduce changeover time 20-35%

- Labor Efficiency: Maintenance teams focus on high-value work instead of reactive firefighting

Revenue Protection (10% of ROI)

- On-Time Delivery: Avoid late delivery penalties ($50K-$500K per incident)

- Customer Retention: Maintain quality standards that prevent customer churn

- Contract Compliance: Meet SLA requirements in automotive/aerospace contracts

Example ROI Calculation (Mid-Sized Manufacturer):

- Annual Revenue: $100M

- Unplanned Downtime Cost: $2M/year (2% of revenue)

- AI Reduces Downtime: 40% → $800K/year savings

- Implementation Cost: $75K

- Payback Period: 1.1 months

- 3-Year ROI: 3,100%

Frequently Asked Questions

Do I need to replace my existing MES or ERP systems?

No. Modern AI platforms are designed to sit on top of your existing infrastructure. AgenixHub uses pre-built connectors to ingest data from systems like SAP, Oracle, Rockwell, and Siemens without requiring a rip-and-replace. We integrate via standard protocols (OPC UA, MQTT, REST APIs) that every major industrial system supports.

Can AI work in air-gapped manufacturing environments?

Yes. Security is paramount, especially for defense contractors and pharmaceutical manufacturers. We support fully on-premises and air-gapped deployments where data never leaves your facility. The AI models are trained on-site, and all inference happens locally. You get the intelligence of AI without the security risks of public clouds.

How accurate is AI for predictive maintenance?

Very accurate. When properly trained, AI models typically achieve 85-95% prediction accuracy on failure events. More importantly, they provide 7-14 days advance warning, which is the critical window for scheduling proactive maintenance during planned downtime rather than reacting to emergency failures at 2 AM.

Do I need a team of data scientists?

Not with the right platform. AgenixHub is “Low-Code / No-Code.” We package complex algorithms into user-friendly tools that your reliability engineers and plant managers can use directly. Your team focuses on interpreting AI insights and making maintenance decisions, not writing Python code.

How much historical data do I need?

Less than you think. While 6-12 months of data is ideal, we can often jumpstart models with “transfer learning” from similar machinery and refine them with just 4-8 weeks of your specific operating data. For brand-new equipment, we use “anomaly detection” approaches that establish a baseline of “normal” operation in real-time.

What if my equipment doesn’t have sensors?

Retrofitting is easier than ever. Wireless IoT sensors can be installed in hours, not days. Temperature, vibration, and current sensors cost $50-$300 each and communicate via low-power wireless protocols (LoRaWAN, NB-IoT). Many manufacturers start with just 10-20 sensors on critical assets and expand coverage over time.

How do I handle change management with my workforce?

Communication is key. Position AI as a “co-pilot” that enhances human expertise, not replaces it. Involve your maintenance technicians early in the pilot. Show them how AI eliminates the frustration of surprise breakdowns and gives them time to perform proactive maintenance that prevents failures. Frame the narrative as “working smarter, not harder.”

Can AI integrate with my CMMS (Computerized Maintenance Management System)?

Yes. We have native integrations with major CMMS platforms (SAP PM, IBM Maximo, Infor EAM). When the AI predicts a failure, it can automatically generate a work order in your CMMS with the predicted failure date, affected asset, recommended parts, and priority level. This closes the loop from prediction to action.

What happens during a network outage?

Edge computing ensures resilience. Critical AI models run on local edge servers, not cloud-only infrastructure. If your internet connection drops, predictive maintenance and quality control continue operating. Data syncs to the cloud when connectivity is restored. For 100% air-gapped environments, everything runs on-premises with zero external dependencies.

Key Takeaways

Remember these 3 things about manufacturing AI in 2025:

- Start Small, Scale Fast: Don’t try to boil the ocean. Pick one high-value problem (like a specific bottling line’s downtime) and solve it first.

- Data Privacy Matters: You don’t have to sacrifice security for intelligence. On-prem AI is real and effective.

- ROI is Immediate: If you aren’t seeing a clear path to value in 90 days, you are likely over-engineering the solution.

Summary

In summary, manufacturing AI implementation is a strategic journey that starts with targeted pilots and scales into facility-wide optimization. By leveraging modern, low-code platforms and prioritizing high-ROI use cases like predictive maintenance and quality control, manufacturers can achieve significant competitive advantages in the 2025 landscape.

Recommended Follow-up:

Need help scoping your project? Schedule a free expert consultation to discuss your specific infrastructure.

Don’t wait 6-18 months for traditional vendors. Deploy manufacturing AI in 2-4 weeks with AgenixHub today.