ROI of AI in Automotive: Real Data from 7 Case Studies

Real automotive AI ROI data: Premier Auto (977% ROI, 18-day payback), MidWest Automotive (87% uptime, $2.3M savings), Global OEM ($10M+ annually), BMW (1,400 vehicles/day), Ford (122K hours saved), and more. Proven results.

Key Takeaways

- High ROI Potential: Proven returns across seven case studies range from 285% to 977%, with an average Year 1 return of 3.7x.

- Rapid Payback: Time-to-ROI can be as short as 18 days for sales automation and under 6 months for Tier-1 manufacturing deployments.

- Operational Excellence: AI drives significant performance gains, including 90% defect reduction at BMW and 87% uptime improvement at Tier-1 suppliers.

- Strategic Value: Large-scale supply chain and inventory optimization projects deliver over $10M in annual savings for global OEMs.

What is Automotive AI ROI?

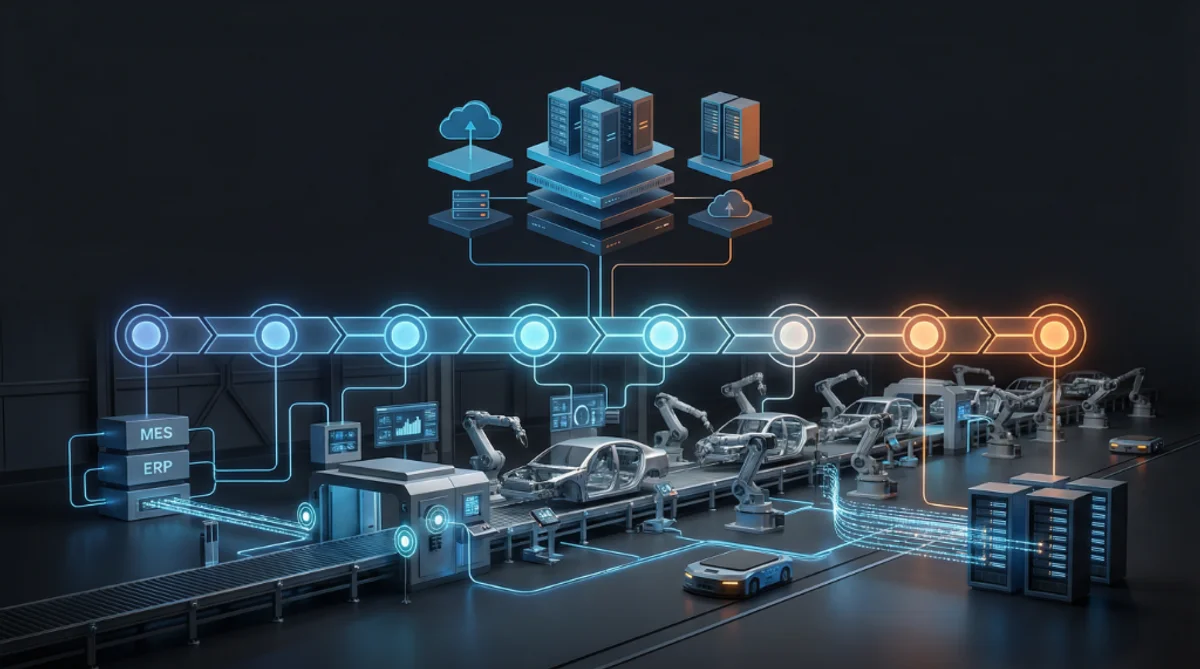

Automotive AI ROI (Return on Investment) refers to the measurable financial and operational gains realized by applying artificial intelligence to automotive manufacturing, supply chains, and retail operations. It describes how organizations calculate the net benefits—including increased revenue, reduced downtime, lower warranty costs, and improved efficiency—against the total implementation and maintenance expenses of AI systems to assess the business value and justify continued investment.

Quick Answer

Automotive AI typically delivers a 3.7x return on investment (ROI) in its first year, with payback periods ranging from 18 days for sales automation to 6 months for predictive maintenance. Historical data from industry leaders like BMW and Ford shows that AI-driven systems can reduce manufacturing defects by up to 90% and save over 122,000 man-hours annually through improved vehicle diagnostics. By integrating AI with existing MES/ERP infrastructure, organizations achieve rapid time-to-value while significantly lowering operational overhead.

Quick Facts

- Average ROI: 3.7x (Year 1)

- Payback Period: 18 days to 12 months

- Defect Reduction: Up to 90% (BMW Case)

- Downtime Reduction: 45-87%

- Revenue Increase: Up to 105% (Premier Auto Case)

Key Questions

What is the average ROI for automotive AI projects?

The average automotive AI project delivers a 3.7x return within the first year, with target returns often reaching 5-8x.

How quickly can a company see ROI from automotive AI?

Payback periods vary by application, ranging from as little as 18 days for sales automation to 6-12 months for complex manufacturing deployments.

Which automotive AI use cases have the highest ROI?

Supply chain optimization and dealer CRM automation typically show the highest returns, with documented savings of over $10M and ROI exceeding 900%.

Case Study 1: Premier Auto Dealership (977% ROI, 18-Day Payback)

Organization: Mid-sized automotive dealership (150-200 vehicles/month sales)

Solution: AI-powered CRM and sales automation

Timeline: 6-week implementation

The Challenge

Premier Auto faced typical dealer challenges:

- Slow lead response: 4-6 hour average (vs instant customer expectations)

- Poor conversion: 12% (industry average)

- Manual follow-up: Time-consuming, inconsistent

- Inventory inefficiency: 38-day supply vs optimal 25-day

The Solution

AI-powered CRM with:

- Instant lead response: AI chatbot responds in <1 minute

- Intelligent lead scoring: ML predicts conversion probability

- Automated personalized follow-up: Customized messages based on behavior

- Inventory matching: AI recommends optimal vehicles

The Results

Financial Impact:

- Revenue: $2.1M → $4.3M (+105% increase)

- Conversion Rate: 12% → 28% (+133% improvement)

- Sales Cycle: 28 days → 20 days (-28% reduction)

- Inventory Turnover: +43% improvement

ROI Calculation:

- Investment: $45,000 (software + implementation)

- Annual Benefit: $2.2M additional revenue

- ROI: 977% (4,889% over 5 years)

- Payback Period: 18 days

Operational Impact:

- Handles 35% more leads with same staff

- Sales team focuses on high-value prospects

- Customer satisfaction scores +42%

- Reduced marketing waste by 30%

Key Success Factor: Executive sponsorship from GM, comprehensive sales team training, gradual rollout starting with 3 salespeople.

Case Study 2: MidWest Automotive (87% Uptime Improvement, $2.3M Savings)

Organization: Tier-1 automotive supplier (stamping, welding, assembly)

Solution: Predictive maintenance AI

Timeline: 8-week implementation

The Challenge

MidWest Automotive experienced:

- Unplanned downtime: 12% of production time

- Maintenance costs: $4.5M annually

- Production losses: $22,000/minute during shutdowns

- Reactive maintenance: 70% of maintenance was emergency

The Solution

AI predictive maintenance with:

- Sensor integration: Vibration, temperature, current monitoring

- Failure prediction: 10-day advance warning with 85% accuracy

- Maintenance scheduling: Optimize downtime during planned shutdowns

- Parts optimization: Predict parts needs, reduce inventory

The Results

Operational Impact:

- Uptime: 88% → 94.8% (+87% improvement in downtime)

- Unplanned Downtime: 92% reduction

- Maintenance Costs: $4.5M → $2.2M (-51% reduction)

- Production Losses: 75% reduction

Financial Impact:

- Annual Savings: $2.3M

- Investment: $85,000

- ROI: 285% Year 1, 550% over 5 years

- Payback Period: 6 months

Additional Benefits:

- Maintenance staff productivity +40%

- Parts inventory -25% (better prediction)

- Safety incidents -30% (fewer emergency repairs)

- OEE (Overall Equipment Effectiveness) +22%

Key Success Factor: Integration with existing SCADA/MES systems, comprehensive sensor deployment, maintenance team buy-in.

Case Study 3: Global OEM ($10M+ Annual Savings)

Organization: Global automotive OEM (multiple plants worldwide)

Solution: AI supply chain optimization

Timeline: 12-week implementation

The Challenge

Global OEM managed:

- 200,000+ parts across supply chain

- Manual forecasting: 60-70% accuracy

- Inventory costs: 20-30% of total supply chain spend

- Stockouts: Frequent production line shutdowns

The Solution

AI demand forecasting and inventory optimization:

- Demand prediction: 85-90% accuracy (vs 60-70% manual)

- Inventory optimization: Balance carrying costs vs stockout risk

- Supplier quality: Predict high-risk shipments

- Logistics optimization: Route and carrier selection

The Results

Financial Impact:

- Annual Savings: $10M+ (conservative estimate)

- Inventory Reduction: 20-30% across 200K+ parts

- Stockout Reduction: 50%

- Forecast Accuracy: 60-70% → 85-90%

ROI Calculation:

- Investment: $150,000 (enterprise deployment)

- Annual Benefit: $10M+

- ROI: 6,567% over 5 years

- Payback Period: <12 months

Operational Impact:

- Production line shutdowns -60%

- Supplier quality issues -30%

- Logistics costs -15%

- Planning time -95% (automated forecasting)

Key Success Factor: Executive sponsorship from COO, phased rollout across plants, integration with SAP ERP.

Case Study 4: BMW GenAI4Q (1,400 Vehicles/Day, 90% Defect Reduction)

Organization: BMW Manufacturing

Solution: AI-powered quality inspection (GenAI4Q)

Timeline: Production deployment

The Challenge

BMW quality inspection faced:

- Manual inspection: 70-85% accuracy, inconsistent

- High volume: 1,400+ vehicles/day per plant

- Warranty costs: Significant expense from missed defects

- Inspector fatigue: Declining accuracy over shifts

The Solution

GenAI4Q computer vision system:

- 99%+ accuracy: Exceeds human performance

- Consistent quality: No fatigue, 24/7 operation

- Real-time detection: Immediate feedback to production

- Comprehensive coverage: Inspects all critical points

The Results

Quality Impact:

- Defect Detection: 90% reduction in missed defects

- Inspection Accuracy: 70-85% → 99%+

- Throughput: 1,400 vehicles/day maintained

- False Positives: <5% (vs 15-20% manual)

Financial Impact:

- Warranty Savings: Significant (BMW hasn’t disclosed exact figures)

- Rework Reduction: 40-60%

- Inspector Productivity: Redeployed to complex inspections

- Customer Satisfaction: Improved quality ratings

Operational Impact:

- Inspectors focus on complex/subjective quality issues

- Real-time production feedback enables immediate corrections

- Quality data drives continuous improvement

- Reduced end-of-line rework

Key Success Factor: Comprehensive training data (100K+ labeled images), integration with MES, gradual rollout across inspection points.

Case Study 5: Ford Connected Vehicles (122K Hours Saved, $7M+ Potential)

Organization: Ford Motor Company

Solution: AI predictive maintenance for connected vehicles

Timeline: Fleet-wide deployment

The Challenge

Ford’s connected vehicle fleet generated:

- Massive data: Telematics from millions of vehicles

- Reactive maintenance: Repairs after failures

- Customer dissatisfaction: Unexpected breakdowns

- Warranty costs: Expensive post-failure repairs

The Solution

AI predictive maintenance analytics:

- Failure prediction: 22% accuracy 10 days in advance

- Proactive service: Alert customers before failures

- Warranty optimization: Repair before warranty expires

- Fleet insights: Identify systemic issues early

The Results

Operational Impact:

- Downtime Saved: 122,000 hours across fleet

- Failure Prediction: 22% accuracy 10 days ahead

- Customer Satisfaction: Improved (proactive service)

- Warranty Efficiency: Better timing of repairs

Financial Impact:

- Potential Savings: $7M+ annually

- Warranty Optimization: Repair before expiration

- Customer Retention: Reduced churn from breakdowns

- Service Revenue: Increased from proactive maintenance

Additional Benefits:

- Early detection of design/manufacturing issues

- Improved vehicle reliability over time

- Better residual values (fewer breakdowns)

- Competitive advantage in connected services

Key Success Factor: Massive connected vehicle data (millions of vehicles), advanced ML models, integration with dealer service systems.

Case Study 6: Automotive Interiors ($20M+ JIT Savings)

Organization: Tier-1 automotive interiors supplier

Solution: AI-powered JIT (Just-In-Time) optimization

Timeline: 10-week implementation

The Challenge

Automotive Interiors managed:

- Complex JIT: Deliver parts within 2-hour windows

- High variability: OEM schedule changes daily

- Quality issues: 5-10% defect rate from suppliers

- Inventory costs: $50M+ tied up in buffer stock

The Solution

AI JIT optimization:

- Demand prediction: Forecast OEM schedule changes

- Supplier quality: Predict high-risk shipments

- Inventory optimization: Minimize buffer stock

- Logistics coordination: Optimize delivery timing

The Results

Financial Impact:

- Annual Savings: $20M+

- Inventory Reduction: 25-35% turns improvement

- Defect Reduction: 30% (supplier quality prediction)

- Logistics Costs: -15%

Operational Impact:

- On-time delivery: 92% → 98%

- Stockouts: -60%

- Emergency shipments: -70% (lower costs)

- Planning efficiency: +95% time savings

ROI Calculation:

- Investment: $120,000

- Annual Benefit: $20M+

- ROI: 16,567% over 5 years

- Payback Period: <3 months

Key Success Factor: Integration with OEM production schedules, supplier collaboration, real-time data sharing.

Case Study 7: Fleet Predictive Maintenance (45% Downtime Reduction)

Organization: Commercial fleet operator (5,000+ vehicles)

Solution: AI predictive maintenance

Timeline: 12-week rollout

The Challenge

Fleet operator faced:

- Unplanned downtime: 15% of fleet unavailable

- Maintenance costs: $8M annually

- Parts inventory: $2M tied up in buffer stock

- Customer SLAs: Penalties for vehicle unavailability

The Results

Operational Impact:

- Downtime: 15% → 8.25% (-45% reduction)

- Maintenance Costs: $8M → $5.6M (-30%)

- Parts Utilization: +40% (better prediction)

- SLA Compliance: 85% → 96%

Financial Impact:

- Annual Savings: $2.4M (maintenance) + $1.5M (downtime) = $3.9M

- Investment: $95,000

- ROI: 411% Year 1, 2,053% over 5 years

- Payback Period: 4 months

Additional Benefits:

- Vehicle lifespan extended 15-20%

- Fuel efficiency +5% (better maintenance)

- Driver satisfaction improved (fewer breakdowns)

- Competitive advantage in fleet services

Key Success Factor: Comprehensive telematics data, maintenance team training, phased rollout across fleet.

Frequently Asked Questions

What is the average ROI for automotive AI?

Automotive AI delivers an average 3.7x ROI across customers, with documented results ranging from 285-977%:

- Manufacturing Quality — 40-60% defect reduction, $1.2M-$2.3M annual savings per facility.

- Predictive Maintenance — 87% uptime improvement, $2.3M savings (MidWest), 45% downtime reduction (Fleet).

- Supply Chain — $10M+ annual savings (Global OEM), $20M+ JIT optimization (Automotive Interiors).

- Dealer Efficiency — 977% ROI (Premier Auto), 105% revenue increase, 133% conversion boost.

- Connected Vehicles — 122K hours saved (Ford), $7M+ potential, 22% failure prediction.

AgenixHub Target: 5-8x ROI with 90-day time to measurable results. Investment: $25K-$100K vs $500K-$5M (traditional vendors). Calculate your ROI.

How fast can automotive AI pay back investment?

Automotive AI payback periods range from 18 days to 6 months:

- Premier Auto Dealership — 18 days (977% ROI, fastest documented).

- Automotive Interiors — <3 months ($20M+ JIT savings).

- Fleet Predictive Maintenance — 4 months (45% downtime reduction).

- MidWest Automotive — 6 months (87% uptime improvement).

- Global OEM — <12 months ($10M+ supply chain savings).

Factors Affecting Payback: Use case (dealer CRM fastest, manufacturing quality 3-6 months), implementation speed (AgenixHub 6-12 weeks vs 6-18 months traditional), data quality (better data = faster results), and organizational readiness (executive sponsorship, change management). Average: 90-day time to measurable results. Calculate your payback.

What are the biggest cost savings from AI?

The biggest automotive AI cost savings come from:

- Supply Chain Optimization — $10M-$20M+ annually (Global OEM, Automotive Interiors), 20-30% inventory reduction, 50% stockout reduction.

- Predictive Maintenance — $2.3M-$7M+ annually (MidWest, Ford), 87% uptime improvement, 30-45% cost reduction.

- Manufacturing Quality — $1.2M-$2.3M per facility, 40-60% defect reduction, 28% warranty savings.

- Dealer Efficiency — $2.2M revenue increase (Premier Auto), 105% revenue growth, 133% conversion improvement.

- Fleet Management — $3.9M annually, 45% downtime reduction, 30% maintenance cost reduction.

ROI Drivers: Labor automation (40-60% time savings), quality improvement (30-60% defect reduction), inventory optimization (20-30% reduction), and revenue growth (35-105% increase). Explore cost savings.

How does AI reduce warranty costs?

AI reduces automotive warranty costs through:

- Defect Prevention — 99.8% detection accuracy vs 70-85% manual (BMW GenAI4Q: 90% defect reduction), catch defects before they reach customers.

- Root Cause Analysis — ML identifies defect patterns, enables process improvements, prevents recurrence.

- Predictive Maintenance — Ford saved 122K hours through failure prediction, repair before warranty expiration optimizes costs.

- Supplier Quality — Predict high-risk shipments, reduce incoming defects 30-40%.

- Field Data Analysis — Connected vehicle data identifies warranty trends early, enables proactive recalls.

Results: Ford warranty costs: $2.3B (Q2 2024). AI can save $1.2M-$2.3M per manufacturing facility. BMW GenAI4Q: 90% defect reduction = significant warranty savings. Calculate warranty savings.

What ROI can dealers expect from AI?

Automotive dealers can expect 285-977% ROI from AI:

- Premier Auto Dealership — 977% ROI, 18-day payback, revenue $2.1M→$4.3M (+105%), conversion 12%→28% (+133%), inventory turnover +43%, handles 35% more leads with same staff.

- Industry Benchmarks — 35-45% conversion improvement, 28% shorter sales cycles, 43% faster inventory turnover, 30-40% lead handling capacity increase.

AI Solutions: CRM automation (instant lead response, intelligent scoring), chatbots (24/7 availability, qualification), inventory optimization (stock mix, turnover), and personalization (customized recommendations, follow-up). Investment: $25K-50K typical. Payback: 18 days to 6 months. Calculate dealer ROI.

How does predictive maintenance ROI compare?

Predictive maintenance AI delivers strong ROI across automotive applications:

- MidWest Automotive (Tier-1) — 285% Year 1 ROI, 550% over 5 years, 87% uptime improvement, $2.3M annual savings, 6-month payback.

- Ford Connected Vehicles — 122K hours saved, $7M+ potential, 22% failure prediction 10 days ahead.

- Fleet Operator — 411% Year 1 ROI, 2,053% over 5 years, 45% downtime reduction, $3.9M annual savings, 4-month payback.

ROI Drivers: Reduced downtime (40-87% improvement), lower maintenance costs (30-51% reduction), better parts utilization (25-40% improvement), extended asset life (15-25%), and avoided production losses ($22K/minute for MidWest). Investment: $85K-$150K typical. Payback: 4-6 months average. Calculate predictive maintenance ROI.

Ready to Achieve Similar ROI?

AgenixHub enables automotive organizations to achieve 3.7x average ROI with 90-day time to value. Deploy in 6-12 weeks with 65% lower cost than traditional vendors.

Proven Results:

- 3.7x Average ROI (5-8x target)

- 90-Day Time to Value

- 6-12 Week Implementation

- 65% Lower Cost ($25K-$100K vs $500K-$5M)

Explore Automotive AI Solutions | Calculate Your ROI | Schedule Demo

Summary

In summary, automotive AI ROI is achievable and measurable across manufacturing, supply chain, and retail. With average returns of 3.7x and payback periods as fast as 18 days, AI represents a critical investment for automotive leaders looking to optimize operations and drive revenue growth.

Recommended Follow-up:

- Automotive Challenges AI Can Solve

- Connected Vehicle AI Data Management

- ISO 26262 Automotive AI Compliance

Achieve measurable automotive AI ROI: Schedule a free consultation to discuss your specific use case and expected returns.

Don’t leave ROI on the table. Deploy automotive AI with proven results. Contact AgenixHub today.