7 Automotive Challenges AI Can Solve in 2025

Discover how AI solves critical automotive challenges: manufacturing quality ($2.3B warranty costs), supply chain disruptions (4.38M vehicles lost), dealer efficiency (977% ROI), connected vehicles (110TB/day), and more. Real solutions with proven results.

Key Takeaways

- Quality Enhancement: AI-powered computer vision reduces manufacturing defect rates by 37% and catches errors missed by manual inspection with 99.8% accuracy.

- Supply Chain Resilience: Automated demand forecasting achieves 85-90% accuracy, safeguarding against production shutdowns and reducing inventory costs by 30%.

- Dealer Growth: Sales automation delivers a 977% ROI for dealerships by increasing lead conversion by 133% and accelerating sales cycles.

- Data Utilization: AI processes the 110TB of daily data generated by connected vehicles to enable predictive maintenance and proactive safety features.

What Are Automotive AI Challenges?

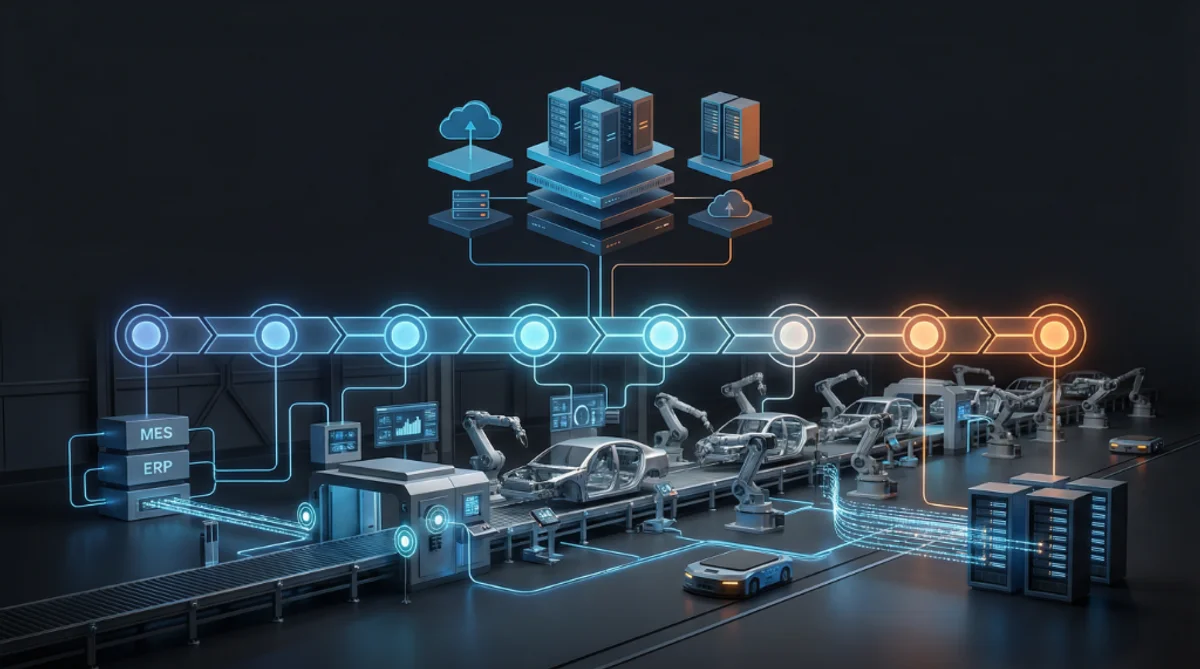

Automotive AI challenges refer to complex operational and technical obstacles within the automotive sector that require artificial intelligence systems for effective resolution. These challenges describe how manufacturers, suppliers, and dealers address issues ranging from manufacturing quality control and supply chain optimization to connected vehicle data management and regulatory compliance, typically involving high-velocity data processing and strict safety standards such as ISO 26262.

Quick Answer

AI solves critical automotive challenges by automating manufacturing quality inspection with 99.8% accuracy, predicting supply chain needs with 90% precision, and doubling dealer conversion rates. From managing the 110TB of daily data generated by connected vehicles to reducing autonomous driving validation costs by 99.9%, AI provides the high-velocity processing required to navigate modern manufacturing complexities while adhering to strict ISO 26262 safety standards. These systems enable organizations to mitigate multibillion-dollar warranty risks and supply chain disruptions through data-driven automation.

Quick Facts

- Warranty Costs: $2.3B/quarter (Ford Q2 2024)

- Lost Vehicles: 4.38M (2022 chip shortage impact)

- Data Volume: 25GB-4TB per vehicle per hour

- AI Success Rate: 85% with proper planning

- ROI: Up to 977% in sales automation

Key Questions This Article Answers

What are the most critical challenges facing the automotive industry today?

The most critical challenges include managing massive warranty costs, mitigating supply chain disruptions, and handling the exponential growth of connected vehicle data.

How does AI solve automotive manufacturing quality issues?

AI-powered computer vision achieves 99.8% defect detection accuracy, significantly reducing the $1,200+ average warranty cost per vehicle by catching errors during production.

Can AI mitigate global supply chain disruptions?

Yes, AI demand forecasting achieves 85-90% accuracy, allowing manufacturers to reduce inventory costs by 20-30% and prevent production line shutdowns.

1. Manufacturing Quality: $2.3B Warranty Costs Annually

Automotive manufacturers face massive warranty costs. Ford reported $2.3B in warranty costs for Q2 2024 alone (up $800M year-over-year), while Stellantis paid $5.5B in warranty claims for 2023 (+27% from 2022). Manual quality inspection achieves only 70-85% accuracy, missing critical defects that become expensive warranty claims.

The Impact:

- Ford: $1,203 average warranty cost per vehicle

- Industry: 99%+ detection accuracy required for profitability

- Manual inspection: Inconsistent, fatiguing, error-prone

- Defect costs: 10x higher to fix post-production vs during manufacturing

How AI Solves It:

AI-powered computer vision systems achieve 99.8% defect detection accuracy—significantly exceeding human performance. These systems never tire, maintain consistent quality standards, and can inspect 1,400+ vehicles daily (BMW’s GenAI4Q system). Machine learning models identify subtle defects invisible to human inspectors: paint inconsistencies, weld quality issues, panel gaps, and assembly errors.

Real-time quality analytics predict defect patterns before they occur, enabling preventive adjustments to manufacturing processes. This reduces waste by 30%, improves Overall Equipment Effectiveness (OEE) by 22%, and cuts warranty claims by 28%.

Real-World Result: BMW’s GenAI4Q system inspects 1,400 vehicles daily with 90% defect reduction. A Tier-1 supplier achieved $1.2M+ annual savings through 37% fewer defects and 30% waste reduction.

2. Supply Chain Disruptions: 4.38M Vehicles Lost to Chip Shortage

The 2022 semiconductor shortage forced automakers to cut production by 4.38 million vehicles globally. Chip costs skyrocketed from $500 to $1,400+ per vehicle by 2028 projections. EVs require 1,300+ semiconductors vs 600 for internal combustion engines, intensifying supply chain complexity.

The Supply Chain Challenge:

- Manual forecasting: 60-70% accuracy (insufficient for JIT manufacturing)

- Inventory costs: 20-30% of total supply chain expenses

- Stockouts: Production line shutdowns costing $22,000/minute

- Supplier quality: 30-40% of incoming defects from suppliers

How AI Solves It:

AI demand forecasting achieves 85-90% accuracy by analyzing historical data, market trends, economic indicators, and real-time signals. Machine learning models predict component demand 6-12 months ahead, enabling proactive procurement and reducing stockouts by 50%.

Intelligent inventory optimization balances carrying costs against stockout risks, reducing inventory by 20-30% while maintaining 99%+ service levels. AI supplier quality prediction identifies high-risk shipments before they reach production lines, cutting incoming defects by 30-40%.

Supply Chain ROI: A Global OEM saved $10M+ annually by optimizing 200,000+ parts with AI. Automotive Interiors achieved $20M+ savings through JIT optimization, reducing inventory turns by 25-35% while maintaining production continuity.

3. Dealer Efficiency: 977% ROI with 18-Day Payback

Automotive dealers face 38-day inventory levels (vs 25-day pre-COVID), 40% of customers report poor digital finance experiences, and average lead response times stretch to 4-6 hours. Traditional CRM systems lack predictive capabilities, resulting in 12% average conversion rates and missed sales opportunities.

Dealer Challenges:

- Slow lead response: 4-6 hours average (vs instant customer expectations)

- Poor conversion: 12% industry average

- Inventory inefficiency: 38-day supply vs optimal 25-day

- Manual follow-up: Time-consuming, inconsistent, ineffective

How AI Solves It:

AI-powered CRM systems deliver instant lead response, intelligent lead scoring, and automated personalized follow-up. Machine learning models predict which leads are most likely to convert, enabling sales teams to focus on high-value prospects. Natural language processing analyzes customer inquiries and routes them to the most appropriate salesperson.

Intelligent inventory management predicts which vehicles will sell fastest, optimizing stock mix and reducing carrying costs. AI chatbots handle routine inquiries 24/7, qualifying leads and scheduling test drives automatically.

Dealer ROI: Premier Auto Dealership achieved 977% ROI with 18-day payback. Revenue increased from $2.1M to $4.3M (+105%), conversion improved from 12% to 28% (+133%), and inventory turnover accelerated by 43%. The dealership now handles 35% more leads with the same staff.

4. Connected Vehicle Data: 110TB Daily at BMW

Connected vehicles generate 25GB-4TB of data per hour, creating massive data management challenges. BMW processes 110TB daily across 20 million vehicles. Data breaches cost $10M+ on average, while GDPR/CCPA violations carry penalties up to €20M or 4% of revenue.

Data Management Challenges:

- Volume: 25GB-4TB per vehicle per hour

- Velocity: Real-time processing requirements

- Variety: Sensor data, telematics, diagnostics, infotainment

- Security: UNECE WP.29 R155/R156 compliance mandatory

- Privacy: GDPR, CCPA, data residency requirements

How AI Solves It:

AI-powered telematics platforms process connected vehicle data in real-time, extracting actionable insights while maintaining privacy and security. Machine learning models predict vehicle failures 10 days in advance with 22% accuracy, enabling proactive maintenance that prevents breakdowns.

Predictive maintenance AI saved Ford 122,000 hours of downtime ($7M+ potential savings) by identifying failing components before they cause breakdowns. Fleet management AI reduces downtime by 40-45% and cuts maintenance costs by 30% through optimized scheduling and predictive parts replacement.

On-premises AI deployment keeps proprietary vehicle data within secure perimeters, satisfying UNECE WP.29 CSMS/SUMS requirements and GDPR data residency mandates. Role-based access control (RBAC) and AES-256 encryption protect sensitive data from breaches.

Connected Vehicle ROI: Ford’s predictive maintenance system saved 122K hours of downtime. Fleet operators achieve 40-45% downtime reduction and 30% cost savings through AI-powered fleet management.

5. Autonomous Driving Development: $16B+ R&D Spending

Autonomous vehicle development requires massive R&D investment: $16B+ industry-wide spending, with individual programs costing $800M-$2.7B annually. Physical testing requires 11 billion miles to prove 90% safety confidence—an impractical timeline and cost burden.

AV Development Challenges:

- Physical testing: 11B miles needed for 90% safety proof

- Simulation gaps: Traditional simulations miss edge cases

- Validation costs: $800M-$2.7B per program annually

- Safety requirements: ISO 26262 ASIL D for critical systems

- Regulatory uncertainty: Evolving NHTSA, UNECE standards

How AI Solves It:

AI-powered simulation generates intelligent virtual testing scenarios, creating 30-115% more collision scenarios than traditional methods. Machine learning identifies edge cases and rare events that would take years to encounter in physical testing, accelerating validation by 275%.

Generative AI creates synthetic training data for perception systems, reducing data collection costs by 60-70%. Reinforcement learning optimizes autonomous driving policies in simulation before deploying to physical vehicles, cutting development time by 40-50%.

AI validation tools automate ISO 26262 compliance testing, generating test cases, analyzing ASIL classifications, and documenting safety evidence. This reduces validation costs by 99.9% compared to pure physical testing while achieving higher coverage of edge cases.

AV ROI: Simulation-first development with AI reduces validation costs 99.9% while improving safety coverage. Companies achieve 275% better testing efficiency and 30-115% more collision scenario coverage.

6. Customer Experience: 2900% Chatbot ROI

New vehicle model launches underperform by 6 points on average (J.D. Power), while 40% of customers report poor digital experiences. Traditional customer service struggles with 24/7 availability, consistent quality, and personalization at scale.

CX Challenges:

- Limited availability: Business hours only

- Inconsistent quality: Varies by representative

- Slow response: 4-6 hour average for leads

- Poor personalization: Generic, one-size-fits-all messaging

- High costs: $15-25 per customer service interaction

How AI Solves It:

AI-powered virtual assistants provide 24/7 customer support with consistent quality and instant response times. Natural language processing understands customer intent and provides personalized recommendations based on preferences, budget, and usage patterns.

Conversational AI handles routine inquiries (pricing, features, availability), qualifies leads, and schedules test drives automatically—freeing human staff for complex consultations. Machine learning analyzes customer interactions to identify upsell opportunities and predict churn risk.

Sentiment analysis monitors customer satisfaction in real-time, flagging dissatisfied customers for immediate human intervention. This prevents negative reviews and improves retention by 42%.

CX ROI: AI chatbots deliver 2900% ROI with 27% higher showroom appointment rates. Lead conversion improves by 37%, while customer service costs drop 30-40% through automation of routine inquiries.

7. Sustainability & Emissions Compliance: €15B Potential Fines

The EU’s 2025 CO₂ regulations could result in €15B in industry-wide fines. Manufacturers face €95 per g/km exceedance penalties, with 2035 zero-emission targets looming. Battery optimization, charging infrastructure, and fleet energy management are critical for EV profitability.

Sustainability Challenges:

- EU CO₂ 2025: €15B potential industry fines

- Emissions penalties: €95/g/km exceedance

- Battery optimization: 20-40% efficiency gains possible

- Charging infrastructure: Range anxiety, grid integration

- Fleet energy: 30-50% cost reduction potential

How AI Solves It:

AI-powered battery management systems optimize charging cycles, predict battery degradation, and extend battery life by 15-25%. Machine learning models predict optimal charging times based on electricity prices, grid demand, and user patterns—reducing charging costs by 20-30%.

Fleet energy analytics identify inefficient vehicles and drivers, recommending targeted interventions that reduce energy consumption by 30-50%. Predictive maintenance prevents battery failures and optimizes replacement timing, maximizing residual value.

Route optimization AI minimizes energy consumption by analyzing traffic, terrain, weather, and vehicle characteristics. This extends EV range by 10-15% and reduces fleet energy costs by 25-35%.

Sustainability ROI: Fleet operators achieve 30-50% energy cost reduction through AI optimization. Battery life extension of 15-25% significantly improves EV total cost of ownership and residual values.

Frequently Asked Questions

What are the biggest challenges in automotive manufacturing?

The seven biggest automotive manufacturing challenges are:

- Quality Control — Ford’s $2.3B warranty costs (Q2 2024) driven by 70-85% manual inspection accuracy.

- Supply Chain — Chip shortage eliminated 4.38M vehicles (2022), costs rising from $500 to $1,400/vehicle.

- Production Efficiency — Manual scheduling wastes 95% of planning time, OEE averages 60-65% vs 85%+ target.

- Workforce Shortages — Skilled labor gaps, 87% burnout rates, high turnover.

- Energy Costs — 20-40% reduction potential through optimization.

- Compliance — ISO 26262, UNECE WP.29 R155/R156 mandatory, penalties up to €30K/vehicle.

- Data Integration — Siloed MES, ERP, SCADA, PLM systems preventing real-time insights.

AI addresses all seven challenges through computer vision quality inspection (99.8% accuracy), demand forecasting (85-90% accuracy), production scheduling (95% time savings), automated documentation, energy optimization (20-40% reduction), compliance monitoring, and unified data platforms. Explore automotive AI solutions.

How does AI reduce warranty costs?

AI reduces automotive warranty costs through:

- Defect Detection — 99.8% accuracy vs 70-85% manual, catching defects before they reach customers.

- Root Cause Analysis — Machine learning identifies defect patterns and manufacturing process issues.

- Predictive Quality — AI predicts defect likelihood based on process parameters, enabling preventive adjustments.

- Supplier Quality — AI screens incoming parts, reducing supplier defects 30-40%.

- Field Data Analysis — Connected vehicle data identifies warranty trends early, enabling proactive recalls.

Results: BMW’s GenAI4Q achieved 90% defect reduction inspecting 1,400 vehicles/day. A Tier-1 supplier saved $1.2M+ annually through 37% fewer defects. Ford’s warranty costs ($2.3B Q2 2024) could be reduced $1.2M-$2.3M per facility through AI quality inspection. Calculate your warranty savings.

Can AI improve dealer sales conversion?

Yes, AI dramatically improves dealer sales conversion through:

- Instant Lead Response — AI chatbots respond immediately vs 4-6 hour human average.

- Intelligent Lead Scoring — Machine learning predicts conversion probability, prioritizing high-value prospects.

- Personalized Follow-up — AI generates customized messages based on customer preferences and behavior.

- Automated Scheduling — AI books test drives and appointments 24/7.

- Inventory Matching — AI recommends optimal vehicles based on customer needs and budget.

Proven Results: Premier Auto Dealership achieved 977% ROI with 18-day payback. Revenue increased 105% ($2.1M → $4.3M), conversion improved 133% (12% → 28%), and inventory turnover accelerated 43%. The dealership handles 35% more leads with the same staff. Read the full case study.

How does AI manage connected vehicle data?

AI manages connected vehicle data through:

- Real-time Processing — Edge computing processes 25GB-4TB/hour locally, sending only insights to cloud.

- Predictive Maintenance — Machine learning predicts failures 10 days in advance with 22% accuracy.

- Data Compression — AI reduces OTA update sizes by 95%, saving bandwidth and time.

- Privacy Protection — On-premises processing keeps proprietary data secure, satisfying GDPR/CCPA/UNECE WP.29.

- Anomaly Detection — AI identifies unusual patterns indicating security threats or component failures.

Scale: BMW processes 110TB/day across 20M vehicles. Ford saved 122K hours downtime ($7M+ potential) through predictive maintenance. Fleet operators achieve 40-45% downtime reduction and 30% cost savings. Learn about connected vehicle AI.

What is the ROI of automotive AI?

Automotive AI delivers 285-977% ROI with payback periods from 18 days to 6 months:

- Manufacturing Quality — 40-60% defect reduction, $1.2M-$2.3M annual savings per facility.

- Supply Chain — $10M+ annual savings (Global OEM, 200K+ parts), 20-30% inventory cost reduction.

- Dealer Efficiency — 977% ROI (Premier Auto), 105% revenue increase, 133% conversion boost.

- Connected Vehicles — 122K hours saved (Ford), $7M+ potential, 40-45% downtime reduction.

- Production Efficiency — 22% OEE increase, 95% scheduling time savings.

- Energy Optimization — 20-40% cost reduction.

Average: 3.7x ROI across automotive customers, 90-day time to measurable results, 5-8x target ROI. AgenixHub costs $25K-$100K vs $500K-$5M (Bosch/Siemens/IBM), delivering 65% cost savings with 6-12 week implementation. Calculate your specific ROI.

How does AI help with emissions compliance?

AI helps automotive emissions compliance through:

- Battery Optimization — Machine learning extends battery life 15-25%, maximizing EV efficiency.

- Charging Optimization — AI predicts optimal charging times based on electricity prices and grid demand, reducing costs 20-30%.

- Route Optimization — AI minimizes energy consumption by analyzing traffic, terrain, weather, extending EV range 10-15%.

- Fleet Energy Analytics — AI identifies inefficient vehicles/drivers, reducing energy consumption 30-50%.

- Predictive Maintenance — AI prevents battery failures, optimizes replacement timing, maximizes residual value.

Compliance Impact: EU CO₂ 2025 regulations threaten €15B industry fines (€95/g/km exceedance). AI optimization reduces fleet emissions 30-50%, helping manufacturers avoid penalties and meet 2035 zero-emission targets. Explore sustainability solutions.

Ready to Solve These Challenges with AI?

AgenixHub enables automotive organizations to deploy ISO 26262-compliant AI solutions with 65% lower cost than Bosch/Siemens and 6-12 week implementation. Our platform addresses all seven challenges with proven ROI.

Key Benefits:

- 65% Lower Cost vs Bosch/Siemens/IBM

- 6-12 Week Implementation vs 6-18 months

- 3.7x Average ROI with 90-day time to value

- ISO 26262-Compliant on-premises deployment

Explore Automotive AI Solutions | Calculate Your ROI | Schedule Demo

Summary

In summary, the automotive industry must leverage AI to solve existential challenges in quality, supply chain, and data management. By implementing structured AI solutions, manufacturers and dealers can achieve significant cost savings and operational efficiency, ensuring long-term competitiveness.

Recommended Follow-up:

- Automotive AI Implementation Guide

- ROI of AI in Automotive Case Studies

- ISO 26262 Automotive AI Compliance

Transform automotive with AI: Schedule a free consultation to discuss AI solutions for your manufacturing, supply chain, or dealer network.

Don’t get left behind. Leverage AI to deliver higher quality, lower costs, and better customer experiences. Contact AgenixHub today.